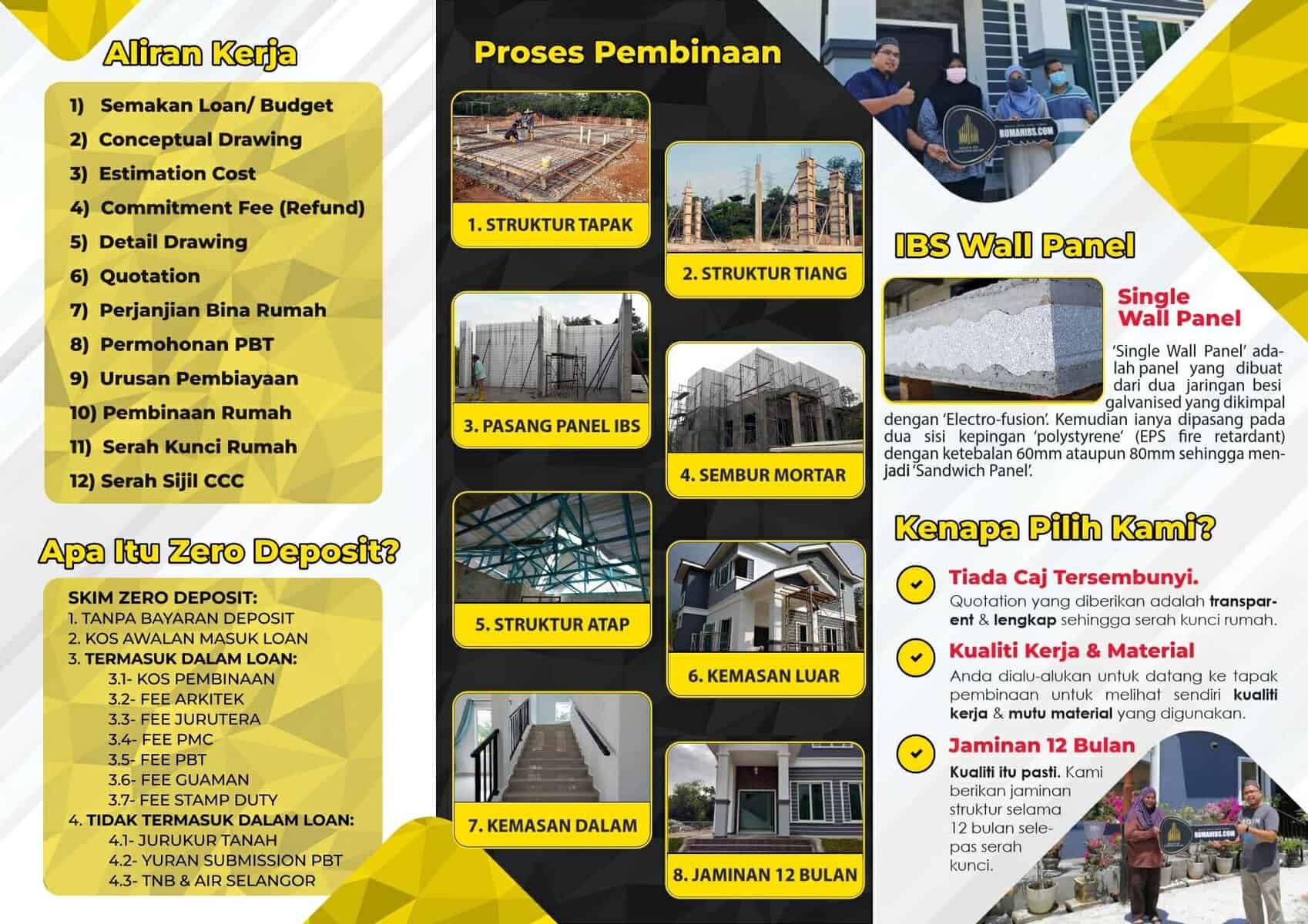

- Bina Rumah Batu-Bata

- Zero Deposit

- Spesifikasi Rumah

- Lokasi Projek

- Pembiayaan LPPSA

- Garis Panduan LPPSA (Rasmi)

- Soalan Lazim LPPSA

- E-Book LPPSA (Download)

- 1. Apa itu LPPSA?

- 2. Kelebihan LPPSA

- 3. Syarat Kelayakan

- 4. Jenis-Jenis Pembiayaan

- Jenis 1 – Pembelian Rumah Kediaman Yang Telah Siap

- Jenis 2 – Membina Rumah Di Atas Tanah Sendiri

- Jenis 3 – Membeli Rumah Kediaman Yang Sedang Dibina

- Jenis 4 – Pembelian Tanah Bagi Pembinaan Rumah

- Jenis 5 – Melunaskan Keseluruhan/ Sebahagian Pinjaman Sedia Ada Daripada Bank/ Institusi Kewangan

- Jenis 6 – Pembinaan Rumah Kediaman Di Atas Tanah Yang Sedang Dibiayai Oleh BPP/ LPPSA

- Jenis 7 – Ubah Suai Rumah Yang Sedang Atau Telah Selesai Bayar Melalui LPPSA

- 5. Semak Kelayakan LPPSA

- 6. Dokumen Yang Diperlukan

- 7. Insurans/ Takaful LPPSA

- 8. Kos Yuran Guaman

- 9. BONUS: Bina Rumah

- Pembiayaan Koperasi

- Pengeluaran KWSP

- Bayaran Tunai

- Kalkulator

Discover the Advantages of IBS Construction in Malaysia

Discover the Advantages of IBS Construction in Malaysia

Introduction

If you’re planning a construction project in Malaysia, it’s important to explore the benefits of Industrialized Building System (IBS) construction. IBS has gained immense popularity in the construction industry due to its numerous advantages over traditional construction methods. In this comprehensive guide, we will delve into the advantages of IBS construction and why it has become the preferred choice for many developers in Malaysia.

Table of Contents

- Introduction to IBS Construction

- Enhanced Efficiency and Speed

- Superior Quality and Consistency

- Cost Savings and Financial Benefits

- Environmental Sustainability

- Enhanced Safety and Reduced On-Site Risks

- Flexibility and Adaptability

- Improved Productivity and Reduced Labor Dependency

- Accelerated Project Completion

- Government Support and Regulatory Framework

- Overcoming Challenges and Limitations

- Integration of Technology in IBS Construction

- Case Studies of Successful IBS Projects

- Future Outlook of IBS Construction in Malaysia

- Conclusion

- FAQs

1. Introduction to IBS Construction

Industrialized Building System (IBS) construction is a method that emphasizes the prefabrication of building components in a controlled factory environment. These components, including walls, floors, columns, and beams, are manufactured off-site and then transported to the construction site for assembly. IBS promotes efficient and systematic construction processes, enabling faster project completion and improved quality control.

2. Enhanced Efficiency and Speed

One of the primary advantages of IBS construction is its enhanced efficiency and speed. By utilizing precast components, construction time is significantly reduced compared to conventional methods. The prefabricated elements are manufactured in a controlled environment, allowing for simultaneous site preparation and component fabrication. This parallel process accelerates construction progress, enabling developers to meet tight project deadlines.

When considering IBS construction, it’s essential to collaborate with experienced manufacturers who can provide timely and precise fabrication of components. This ensures a seamless workflow and maximizes the efficiency and speed of the construction process.

3. Superior Quality and Consistency

IBS construction ensures superior quality and consistency in building projects. With standardized manufacturing processes in controlled factory conditions, the risk of human error is minimized. Precise measurements and quality control measures are implemented during the production of IBS components, resulting in high-quality and consistent building elements. This attention to detail enhances the durability and longevity of the constructed buildings.

To ensure the highest quality standards, it’s crucial to work with reputable IBS manufacturers who follow stringent quality control procedures. Conduct thorough research and engage with manufacturers who have a proven track record of delivering top-notch prefabricated components.

4. Cost Savings and Financial Benefits

Implementing IBS construction methods can lead to significant cost savings and financial benefits for developers. Although the initial investment in setting up the necessary facilities for manufacturing IBS components may be higher, the long-term benefits outweigh the costs. Reduced labor requirements, shortened construction time, and improved resource management contribute to cost savings. Additionally, the use of IBS can potentially lower maintenance and operational costs over the lifespan of the building.

To maximize cost savings, it’s important to conduct a thorough cost analysis and compare it with traditional construction methods. Consider factors such as labor costs, material wastage, project duration, and maintenance expenses. This analysis will provide a comprehensive understanding of the financial benefits associated with IBS construction.

5. Environmental Sustainability

IBS construction aligns with sustainable development goals by reducing the environmental impact of construction projects. The prefabrication process in controlled factory conditions minimizes waste generation and promotes efficient resource utilization. Moreover, the use of environmentally friendly materials and efficient construction techniques further reduces the carbon footprint. By adopting IBS, developers contribute to a greener and more sustainable future.

To ensure the highest level of environmental sustainability, opt for IBS manufacturers who prioritize eco-friendly practices and materials. Look for certifications or accreditations that validate their commitment to sustainable construction.

6. Enhanced Safety and Reduced On-Site Risks

Safety is a paramount concern in any construction project. IBS construction enhances safety levels by minimizing on-site risks and hazards. Since the majority of construction activities take place in the factory, workers are exposed to fewer hazardous conditions commonly found on traditional construction sites. This reduction in on-site risks significantly improves workplace safety, leading to a safer working environment for construction personnel.

To ensure a safe construction environment, it’s important to prioritize worker training and provide them with the necessary safety equipment. Collaborate with manufacturers who prioritize employee safety and follow strict safety protocols during component fabrication.

7. Flexibility and Adaptability

IBS construction offers flexibility and adaptability in design and construction processes. The modular nature of prefabricated components allows for easy customization and modifications. Developers have the flexibility to incorporate design changes and adapt to evolving project requirements without compromising construction quality. This versatility enables efficient utilization of space and provides architects and designers with greater freedom to create innovative and functional structures.

When planning an IBS construction project, collaborate closely with architects and designers to ensure that the project requirements align with the capabilities of IBS construction. This collaborative approach will enable seamless integration of design changes and result in a highly customized and adaptable building.

8. Improved Productivity and Reduced Labor Dependency

IBS construction methods contribute to improved productivity and reduced labor dependency. The use of prefabricated components streamlines the construction process, reducing the need for manual labor on-site. With fewer workers required, developers can mitigate labor-related challenges such as skill shortages and dependency on foreign labor. This increased productivity leads to cost savings and enhanced construction efficiency.

To optimize productivity, it’s important to plan the construction schedule meticulously and ensure that the prefabricated components are delivered on time. Timely coordination between different stakeholders, such as manufacturers, contractors, and suppliers, is essential to avoid delays and maximize productivity.

9. Accelerated Project Completion

Time is a critical factor in the construction industry. IBS construction facilitates accelerated project completion by eliminating time-consuming activities associated with conventional construction methods. The simultaneous production of components and on-site preparation significantly reduces construction duration. This advantage is particularly beneficial in projects with tight timelines, enabling developers to deliver completed buildings to clients in a shorter timeframe.

When embarking on an IBS construction project, consider the project timeline and set realistic milestones. Effective project management and coordination are vital to ensure that each construction phase proceeds smoothly, ultimately leading to accelerated project completion.

10. Government Support and Regulatory Framework

The Malaysian government recognizes the benefits of IBS construction and has actively supported its adoption through various policies and incentives. The Construction Industry Development Board (CIDB) of Malaysia has implemented initiatives to promote IBS and encourage its usage in both public and private sector projects. This government support provides an enabling environment for developers to embrace IBS methods and reap the associated benefits.

Stay updated with the latest government policies and incentives related to IBS construction. Engage with industry associations and consult with professionals who are well-versed in government regulations. This will ensure that your project complies with the required standards and qualifies for any available benefits.

11. Overcoming Challenges and Limitations

While IBS construction offers numerous advantages, it also comes with its own set of challenges and limitations. These include initial investment costs, transportation logistics, design restrictions, and the need for skilled labor in the manufacturing process. However, with proper planning, collaboration, and technological advancements, these challenges can be effectively addressed, making IBS construction a viable choice for developers in Malaysia.

Thoroughly assess the challenges and limitations associated with IBS construction for your specific project. Seek expert advice and engage with experienced professionals who can provide insights on overcoming these challenges. This proactive approach will help you navigate potential hurdles and ensure a successful IBS construction project.

12. Integration of Technology in IBS Construction

Technology plays a vital role in enhancing the effectiveness and efficiency of IBS construction. Innovations such as Building Information Modeling (BIM), 3D printing, and robotic automation have revolutionized the construction industry. These technologies streamline design, manufacturing, and assembly processes, further optimizing construction timelines and improving quality control.

Stay abreast of the latest technological advancements in the construction industry, particularly those relevant to IBS construction. Explore opportunities to integrate technology into your project, whether it’s through advanced design software or automated manufacturing processes. Embracing technology will enhance the overall efficiency and productivity of your IBS construction project.

13. Case Studies of Successful IBS Projects

Numerous successful IBS projects have been completed in Malaysia, showcasing the advantages of this construction method. These case studies demonstrate the successful implementation of IBS in various building types, including residential, commercial, and institutional projects. Examining these projects provides real-life examples of the benefits and achievements that can be realized through IBS construction.

Research and analyze case studies of successful IBS projects in Malaysia. Understand the specific challenges faced by each project and how they were overcome. Extract key learnings and best practices from these case studies to optimize your own IBS construction project.

14. Future Outlook of IBS Construction in Malaysia

The future of IBS construction in Malaysia looks promising. As developers and stakeholders continue to recognize the advantages of this construction method, its adoption is expected to increase. Government support, technological advancements, and the growing emphasis on sustainability will further drive the growth of IBS in the Malaysian construction industry. The continued integration of IBS will contribute to faster project completion, improved quality, and a more sustainable built environment.

Keep a close eye on industry trends and future developments related to IBS construction. Engage with industry experts, attend seminars and conferences, and participate in industry associations to stay informed about the latest advancements. This proactive approach will position you at the forefront of the IBS construction industry in Malaysia.

15. Conclusion

In conclusion, the advantages of IBS construction in Malaysia are undeniable. Enhanced efficiency and speed, superior quality and consistency, cost savings, environmental sustainability, enhanced safety, flexibility, and improved productivity are just some of the benefits that developers can enjoy by adopting IBS methods. With government support and technological advancements, IBS construction is poised to revolutionize the Malaysian construction industry, paving the way for a more efficient, sustainable, and prosperous future.

FAQs

Q1: Is IBS construction only suitable for specific types of buildings? A: No, IBS construction can be applied to a wide range of building types, including residential, commercial, and institutional projects.

Q2: Are there any limitations to the design flexibility of IBS construction? A: While IBS construction offers design flexibility, certain limitations may arise due to the modular nature of prefabricated components. However, innovative design solutions can often overcome these limitations.

Q3: How does IBS construction contribute to environmental sustainability? A: IBS construction promotes environmental sustainability through reduced waste generation, efficient resource utilization, and the use of environmentally friendly materials and construction techniques.

Q4: Are there any financial incentives or grants available for IBS construction in Malaysia? A: Yes, the Malaysian government provides various incentives and grants to encourage the adoption of IBS construction in both public and private sector projects.

Q5: Does IBS construction require specialized skills and labor? A: While IBS construction requires skilled labor for component manufacturing, the overall labor dependency is reduced compared to traditional construction methods.

In conclusion, IBS construction offers a multitude of advantages that can positively impact construction projects in Malaysia. By embracing IBS methods, developers can enjoy enhanced efficiency, superior quality, cost savings, and environmental sustainability. With government support, technological advancements, and a focus on safety and sustainability, the future of IBS construction in Malaysia looks promising. So why wait? Start exploring the benefits of IBS construction and embark on your next construction project with confidence.