Blog

Ensuring Safety and Quality in IBS Construction

Ensuring Safety and Quality in IBS Construction

Table of Contents

- Introduction

- Understanding IBS Construction

- Planning and Designing for Safety and Quality

- Procurement and Material Selection

- Manufacturing and Fabrication Processes

- Transportation and Logistics Considerations

- On-Site Installation and Assembly

- Quality Control and Inspection

- Training and Education for Workers

- Compliance with Regulations and Standards

- Maintaining Safety and Quality throughout the Life Cycle

- Challenges and Solutions in IBS Construction

- Case Studies: Successful Implementations

- Future Trends in IBS Construction

- Conclusion

- Frequently Asked Questions (FAQs)

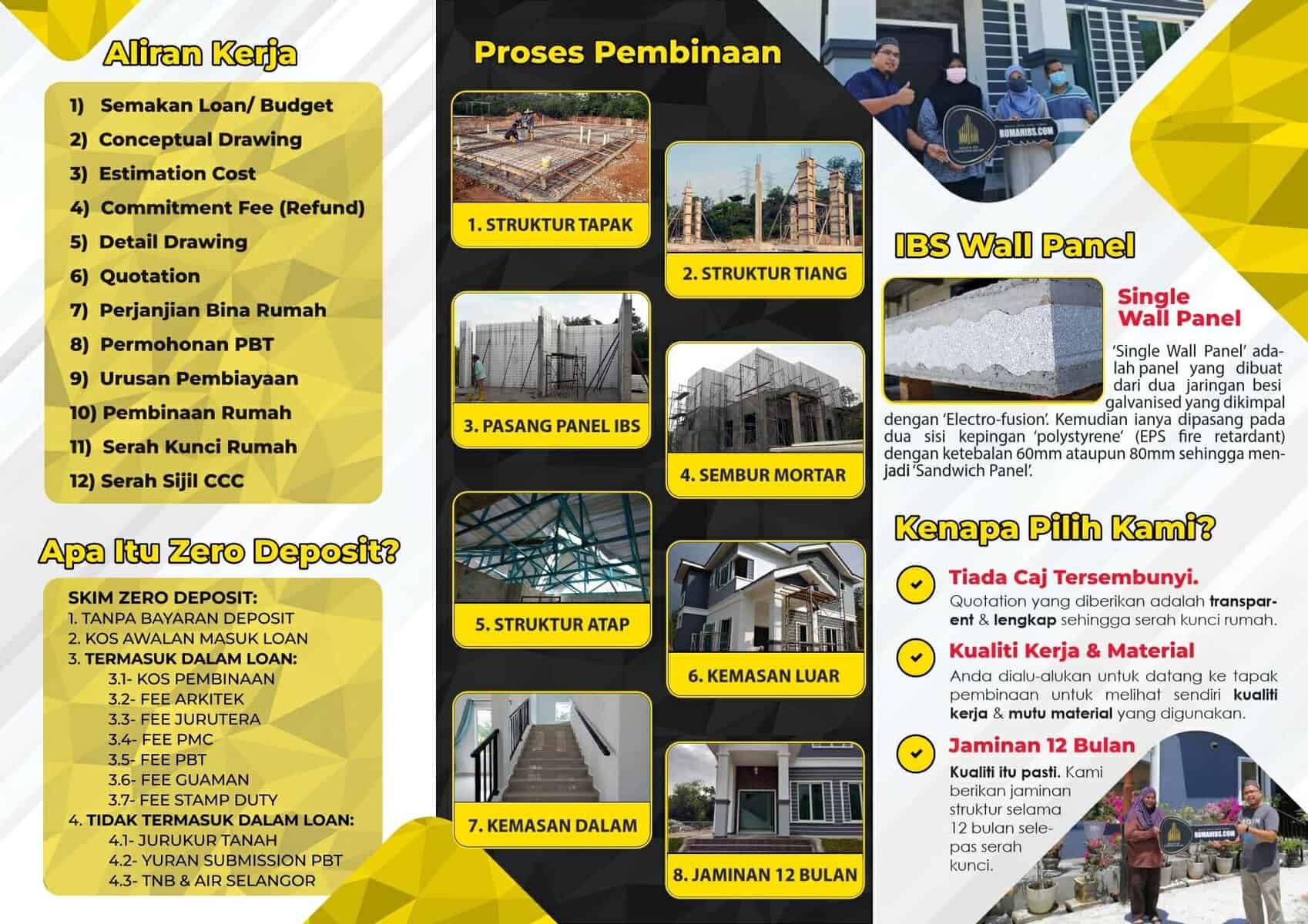

1. Introduction

In the construction industry, safety and quality are of utmost importance. Industrialized Building Systems (IBS) construction offers various benefits, such as improved efficiency and reduced construction time. However, ensuring safety and quality in IBS construction requires careful planning and implementation of best practices. This article explores the key aspects of ensuring safety and quality in IBS construction projects and provides valuable insights for industry professionals and stakeholders.

2. Understanding IBS Construction

Before delving into safety and quality considerations, it’s essential to understand the basics of IBS construction. IBS refers to the use of prefabricated components manufactured off-site and then transported to the construction site for assembly. This construction method offers advantages like enhanced productivity, reduced material waste, and improved construction speed.

3. Planning and Designing for Safety and Quality

The planning and design phase sets the foundation for safety and quality in IBS construction. Designers and engineers must consider factors like structural integrity, load-bearing capacity, fire resistance, and weather resilience. By incorporating safety measures and adhering to building codes, potential hazards can be identified and mitigated early in the process.

4. Procurement and Material Selection

Procurement and material selection play a crucial role in ensuring safety and quality. Engaging reliable suppliers and manufacturers who comply with industry standards is vital. The selection of high-quality materials that meet the project’s requirements is equally important. Thorough evaluation and assessment of suppliers and materials can help avoid potential risks and ensure long-term durability.

5. Manufacturing and Fabrication Processes

IBS components are manufactured off-site, requiring stringent quality control measures. Manufacturers must adhere to established standards and conduct regular inspections to ensure compliance. Robust quality management systems and certifications, such as ISO, contribute to the reliability and consistency of the manufactured components. Implementing advanced manufacturing techniques and embracing automation can also improve quality and precision.

6. Transportation and Logistics Considerations

The transportation of IBS components from the manufacturing facility to the construction site demands careful planning and coordination. Adequate packaging and secure loading methods are crucial to prevent damage during transit. Logistics considerations, such as route planning and optimizing delivery schedules, ensure timely arrival of components. Proper handling and unloading procedures at the construction site further contribute to safety and quality.

7. On-Site Installation and Assembly

Skilled workers familiar with IBS construction techniques are essential for the on-site installation and assembly process. Adequate training and supervision are necessary to ensure safe and accurate construction practices. Compliance with installation guidelines and thorough quality checks during assembly help maintain the structural integrity of the building.

8. Quality Control and Inspection

Quality control and inspection procedures are crucial at various stages of IBS construction. Regular inspections should encompass both individual components and the assembled structure to identify any defects, deviations, or non-compliance issues. By implementing comprehensive quality control measures, construction professionals can ensure that safety and quality standards are consistently met.

9. Training and Education for Workers

Investing in training and education for workers involved in IBS construction enhances safety and quality. Training programs should cover IBS-specific construction techniques, safety protocols, and quality control procedures. Empowering workers with the necessary skills and knowledge fosters a culture of safety and promotes efficient construction practices.

10. Compliance with Regulations and Standards

Adhering to relevant regulations and standards is vital in IBS construction. Compliance ensures that the constructed buildings meet safety and quality benchmarks. Regular audits and assessments help verify compliance, identify areas for improvement, and promptly address any non-conformities. Staying up-to-date with evolving regulations and implementing best practices fosters a safe and compliant construction environment.

11. Maintaining Safety and Quality throughout the Life Cycle

Ensuring safety and quality in IBS construction is an ongoing process that extends beyond the construction phase. Regular maintenance, inspections, and proactive repairs are necessary to preserve the integrity of IBS components and ensure long-term safety. This approach also extends the lifespan of the building and enhances occupant well-being.

12. Challenges and Solutions in IBS Construction

Implementing safety and quality measures in IBS construction comes with specific challenges. These challenges may include logistical complexities, coordination issues, and the need for specialized skills. Effective project management, collaboration between stakeholders, and embracing innovative technologies are key solutions to overcome these challenges and enhance safety and quality in IBS construction.

13. Case Studies: Successful Implementations

Examining successful case studies of IBS construction projects provides practical insights and best practices. Real-world examples demonstrate how safety and quality were prioritized, leading to successful outcomes. These case studies offer valuable lessons for construction professionals and help drive continuous improvement in the industry.

14. Future Trends in IBS Construction

The future of IBS construction holds exciting possibilities. Technological advancements, such as robotics, 3D printing, and digitalization, are expected to further enhance safety, quality, and efficiency. Embracing sustainable practices, implementing modular design approaches, and optimizing construction processes will shape the future of IBS construction.

15. Conclusion

Ensuring safety and quality in IBS construction is paramount to successful project outcomes. By prioritizing careful planning, adherence to regulations, quality control measures, and continuous improvement, stakeholders can deliver buildings that meet the highest standards. Investing in training, collaboration, and embracing emerging technologies will contribute to the advancement of safety and quality in IBS construction.

16. Frequently Asked Questions (FAQs)

16.1 What is IBS Construction, and What are Its Benefits?

IBS (Industrialized Building Systems) construction refers to the use of prefabricated components that are manufactured off-site and later assembled on-site to construct buildings. It is a modern construction method that deviates from the traditional on-site construction approach. The key principle of IBS construction is to shift a significant portion of the construction work to controlled factory environments, where standardized components are manufactured using advanced technologies.

The benefits of IBS construction are numerous. First and foremost, it offers enhanced efficiency and productivity. By manufacturing components off-site, construction projects can be completed at a faster pace, reducing the overall construction duration. This leads to cost savings and faster return on investment.

IBS construction also significantly reduces material waste. With components being manufactured in a controlled environment, material usage can be optimized, minimizing wastage and promoting sustainability. Additionally, the use of standardized components improves construction quality and consistency. The manufacturing process allows for stricter quality control, ensuring that the components meet predefined standards and specifications.

Furthermore, IBS construction provides improved site safety. With a significant portion of the construction work being shifted off-site, the on-site activities are streamlined, reducing the exposure to hazardous construction processes. This promotes a safer working environment for construction workers and reduces the risk of accidents.

In summary, IBS construction offers benefits such as enhanced efficiency, reduced construction duration, cost savings, sustainability through reduced material waste, improved construction quality, and increased site safety.

16.2 How Can Safety be Ensured in IBS Construction Projects?

Ensuring safety in IBS construction projects requires a comprehensive approach that covers various stages of the construction process. Here are key measures to ensure safety:

- Design considerations: During the planning and design phase, safety considerations should be integrated. This includes incorporating structural stability, fire resistance, and adequate escape routes.

- Component quality control: Rigorous quality control measures should be implemented during the manufacturing of IBS components. Adhering to established standards and conducting regular inspections ensure that the components meet safety requirements.

- Transportation and logistics: Proper handling, packaging, and secure transportation methods must be employed to prevent damage to the components during transit. Well-coordinated logistics and adherence to safety protocols during loading and unloading are crucial.

- On-site safety practices: Skilled workers must be trained in IBS construction techniques and safety protocols. Strict adherence to safety guidelines, including the use of personal protective equipment (PPE), is essential during on-site installation and assembly.

- Quality control and inspections: Regular inspections at various stages of construction help identify any defects, deviations, or non-compliance issues. Thorough quality checks ensure that the assembled structure meets safety standards.

- Training and education: Ongoing training programs for workers, supervisors, and site personnel promote safety awareness and best practices in IBS construction. Workers should be educated about potential hazards and trained to respond appropriately.

- Compliance with regulations: Adhering to relevant building codes, safety regulations, and industry standards is paramount. Regular audits and assessments ensure compliance and prompt resolution of any non-compliance issues.

By implementing these safety measures at each stage of the IBS construction process, construction projects can be executed with a strong focus on safety.

16.3 Factors to Consider During the Planning and Design Phase of IBS Construction

The planning and design phase of IBS construction is critical for a successful project. Several factors should be considered to ensure a well-executed construction plan:

- Structural considerations: The structural integrity of the building must be thoroughly analyzed and designed to withstand the required loads and forces. Structural stability should be assessed, and appropriate design measures, such as connections and reinforcements, should be incorporated.

- Modularity and standardization: Designing with modularity and standardization in mind facilitates efficient production and assembly of IBS components. Standardized module sizes and connection details enable seamless integration and reduce design complexities.

- Building services integration: The integration of building services, such as electrical, mechanical, and plumbing systems, should be carefully planned during the design phase. Coordination with the IBS components ensures proper routing and installation of services, optimizing efficiency and functionality.

- Fire safety and acoustic considerations: Fire resistance and acoustic performance are critical factors in building design. Implementing fire-rated materials and ensuring proper acoustic insulation contribute to the overall safety and comfort of the building occupants.

- Aesthetics and architectural features: While IBS construction emphasizes efficiency, aesthetic considerations should not be overlooked. Designing for visual appeal and incorporating architectural features can enhance the building’s attractiveness and marketability.

- Sustainability and energy efficiency: Incorporating sustainable design principles and energy-efficient features can contribute to long-term environmental benefits and cost savings. Designing for natural lighting, ventilation, and renewable energy integration are some examples of sustainable design practices.

- Constructability and logistics: Considering the constructability of the design is crucial. Designers should take into account the transportation and assembly processes of the IBS components, ensuring that they are feasible and efficient.

By carefully addressing these factors during the planning and design phase, IBS construction projects can be optimized for efficiency, functionality, safety, and aesthetic appeal.

16.4 Challenges in Implementing IBS Construction Methods and How to Overcome Them

Implementing IBS construction methods can present several challenges, but with proper strategies, these challenges can be overcome. Here are some common challenges and their corresponding solutions:

- Limited awareness and understanding: Lack of awareness and understanding of IBS among stakeholders can hinder adoption. Overcoming this challenge requires comprehensive education and awareness programs targeting architects, engineers, developers, and government bodies. Sharing success stories and showcasing the benefits of IBS construction can help dispel misconceptions.

- Resistance to change: Resistance to change is a common challenge in the construction industry. To overcome this, stakeholders need to be involved early in the decision-making process. Engaging all parties and addressing concerns through open communication and collaboration can help build confidence and facilitate smoother adoption.

- Design complexities: Designing for IBS construction can be more complex than traditional construction methods. It requires specialized knowledge and consideration of manufacturing and assembly processes. Engaging experienced IBS consultants or partnering with IBS manufacturers during the design phase can help overcome these complexities and optimize the design for efficient construction.

- Supply chain coordination: Coordinating the supply chain in IBS construction projects is crucial to ensure timely delivery of components. Collaborating closely with suppliers, manufacturers, and logistics providers helps streamline the supply chain and minimize delays. Establishing clear communication channels and effective project management practices contribute to efficient coordination.

- Skilled labor and workforce transition: Shifting from traditional construction methods to IBS requires a skilled workforce with expertise in manufacturing and assembly processes. Investing in training and upskilling programs for workers and providing incentives for workforce transition can address the challenge of skilled labor shortage and facilitate the adoption of IBS.

- Regulatory and code compliance: Adapting existing regulations and building codes to accommodate IBS construction methods can be challenging. Engaging with regulatory authorities and actively participating in the development of guidelines specific to IBS construction helps ensure compliance and regulatory support.

By addressing these challenges through collaboration, education, awareness, and strategic planning, the implementation of IBS construction methods can be successfully accomplished.

16.5 Future Trends and Innovations in IBS Construction

The future of IBS construction holds exciting possibilities as technological advancements and innovative approaches continue to shape the industry. Here are some notable trends and innovations to watch for:

- Digitalization and Building Information Modeling (BIM): The integration of digital technologies, such as BIM, enables enhanced collaboration, visualization, and data-driven decision-making throughout the construction lifecycle. BIM facilitates efficient project planning, clash detection, and optimized construction processes.

- Robotics and automation: Robotics and automation are revolutionizing IBS construction. Robotic systems can handle repetitive tasks, such as panel assembly and installation, with high precision and efficiency. Automation streamlines manufacturing processes, reducing manual labor and increasing productivity.

- Prefabricated modular solutions: Prefabricated modular solutions are becoming more sophisticated and diverse. Off-site manufacturing of complete building modules, including finishes and fittings, allows for faster construction and improved quality control. This trend promotes higher levels of standardization and customization in IBS construction.

- Energy-efficient and sustainable IBS: The integration of sustainable design principles and energy-efficient features continues to be a focus in IBS construction. Innovations in building materials, renewable energy systems, and smart technologies contribute to energy-efficient and environmentally friendly IBS projects.

- 3D printing and advanced materials: 3D printing technology offers new possibilities in IBS construction. It enables the fabrication of complex geometries and customized components with precision. The use of advanced materials, such as carbon fiber-reinforced polymers, further enhances the structural integrity and durability of IBS components.

- Circular economy and waste reduction: The circular economy concept is gaining traction in IBS construction. Emphasizing the reuse, recycling, and repurposing of IBS components reduces waste and promotes sustainable practices. Implementing circular economy principles aligns with environmental goals and resource conservation.

By embracing these future trends and innovations, IBS construction in Malaysia can achieve greater efficiency, sustainability, and safety while meeting the evolving needs of the construction industry.