Blog

Innovations in IBS Construction: A Look into the Future

Innovations in IBS Construction: A Look into the Future

Table of Contents

- Introduction

- Understanding IBS Construction

- Benefits of IBS Construction 3.1 Speed and Efficiency 3.2 Quality and Consistency 3.3 Cost Savings 3.4 Safety and Risk Reduction 3.5 Sustainability and Environmental Impact

- Technological Advancements in IBS 4.1 3D Printing 4.2 Augmented Reality (AR) 4.3 Internet of Things (IoT) 4.4 Artificial Intelligence (AI) and Machine Learning 4.5 Advanced Materials and Prefabrication Techniques

- Automation and Robotics in IBS

- Integration of Building Information Modeling (BIM)

- Challenges and Limitations of IBS Construction 7.1 Regulatory and Code Compliance 7.2 Skilled Workforce 7.3 Logistics and Transportation

- The Future of IBS Construction

- Conclusion

- FAQs

1. Introduction

Innovations in the construction industry continue to shape the way buildings are designed, constructed, and managed. One such innovation that holds immense potential is Industrialized Building Systems (IBS) construction. This article explores the future of IBS construction and the transformative impact it can have on the industry.

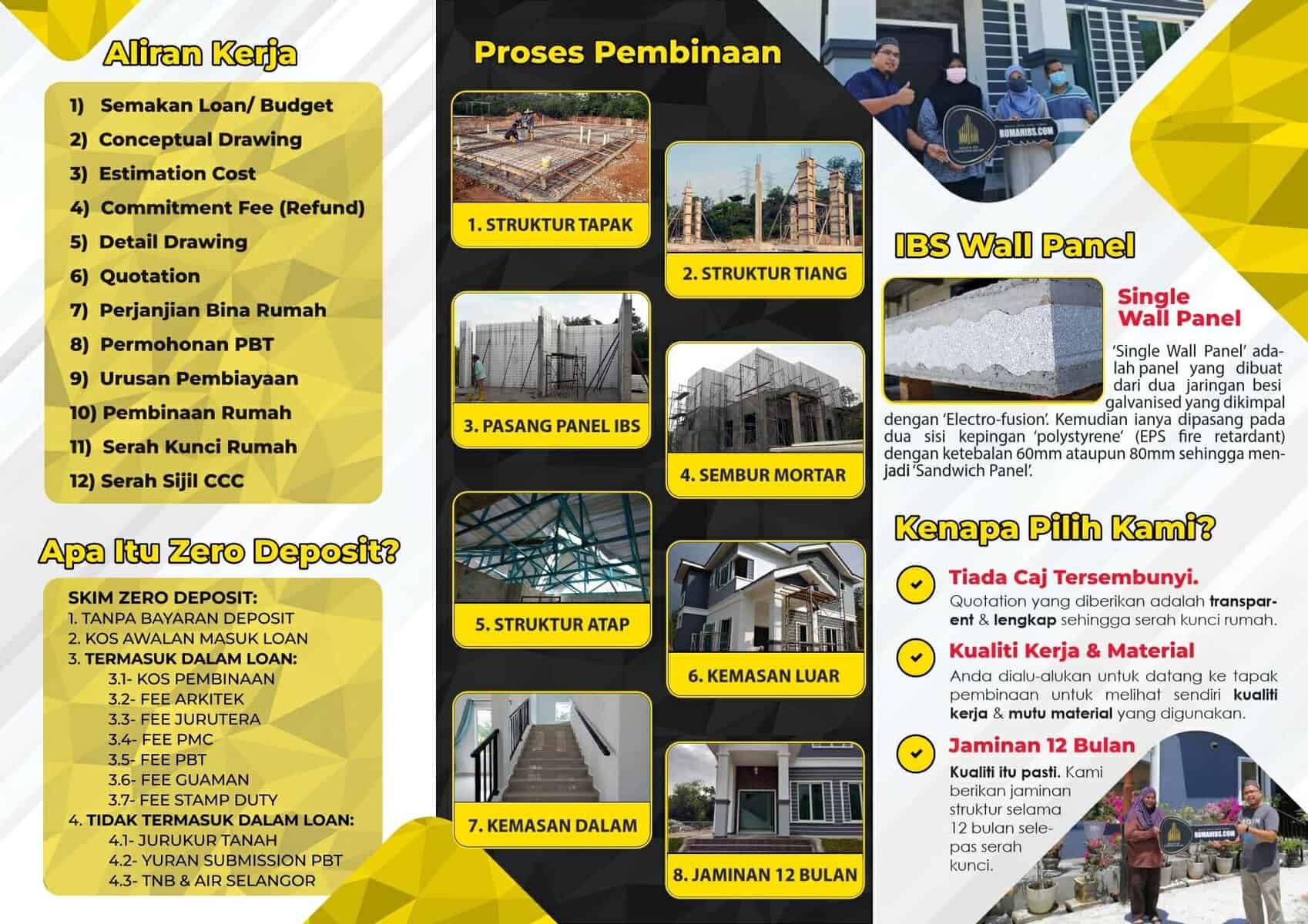

2. Understanding IBS Construction

Industrialized Building Systems (IBS) construction refers to an approach that utilizes off-site manufacturing and assembly processes to enhance efficiency, quality, and sustainability in construction projects. IBS involves the prefabrication of building components in a controlled environment, which are then transported to the construction site for assembly.

3. Benefits of IBS Construction

IBS construction offers numerous benefits that make it an attractive choice for the future of the industry.

3.1 Speed and Efficiency

By utilizing standardized and modular building components, IBS construction significantly reduces construction time compared to traditional methods. The off-site manufacturing process allows for parallel construction activities, resulting in accelerated project timelines.

3.2 Quality and Consistency

IBS construction ensures high-quality outcomes due to the controlled manufacturing environment and precise fabrication processes. The standardized components also promote consistency across different projects, reducing the risk of errors and defects.

3.3 Cost Savings

Efficiency gains in IBS construction translate into cost savings. The reduced construction time, minimized material waste, and improved labor productivity contribute to overall project cost reduction.

3.4 Safety and Risk Reduction

The off-site manufacturing process in IBS construction reduces on-site risks and hazards. Workers are exposed to fewer construction site dangers, leading to improved safety outcomes.

3.5 Sustainability and Environmental Impact

IBS construction promotes sustainability by optimizing material usage and reducing waste. Additionally, the integration of renewable energy systems, energy-efficient designs, and smart building technologies further enhances the environmental performance of IBS projects.

4. Technological Advancements in IBS

The future of IBS construction is closely intertwined with technological advancements that enhance its capabilities. Several key technologies are driving innovation within the IBS domain.

4.1 3D Printing

3D printing has the potential to revolutionize IBS construction by enabling the additive manufacturing of building components. This technology allows for customization, complex geometries, and rapid prototyping, offering architects and builders new design possibilities.

4.2 Augmented Reality (AR)

Augmented Reality (AR) is transforming the way construction professionals visualize and interact with building designs. AR technology allows for the superimposition of virtual models onto the physical environment, enabling better collaboration, design reviews, and on-site construction guidance.

4.3 Internet of Things (IoT)

The Internet of Things (IoT) facilitates the integration of sensor-enabled components and devices in IBS construction. IoT-enabled systems collect real-time data, enabling remote monitoring, predictive maintenance, and enhanced energy efficiency in buildings.

4.4 Artificial Intelligence (AI) and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) technologies are revolutionizing the construction industry. In the context of IBS construction, AI and ML algorithms can analyze vast amounts of data to optimize building designs, predict structural performance, and automate quality control processes.

4.5 Advanced Materials and Prefabrication Techniques

Advancements in materials science and prefabrication techniques are driving innovation within IBS construction. Lightweight and high-strength materials, such as composite panels and engineered timber, offer improved performance and sustainability. Prefabrication techniques like modular construction and panelized systems enable faster assembly and greater design flexibility.

5. Automation and Robotics in IBS

Automation and robotics play a pivotal role in the future of IBS construction. Robots can be deployed for tasks such as material handling, assembly, and on-site construction. Automation not only improves productivity but also ensures precision, reduces labor dependency, and enhances safety.

6. Integration of Building Information Modeling (BIM)

The integration of Building Information Modeling (BIM) with IBS construction enhances project coordination and collaboration. BIM provides a digital representation of a building, allowing stakeholders to visualize, simulate, and optimize the construction process. This integration enables better design coordination, clash detection, and improved facility management throughout the building’s lifecycle.

7. Challenges and Limitations of IBS Construction

While IBS construction offers significant advantages, it also faces challenges that need to be addressed for widespread adoption.

7.1 Regulatory and Code Compliance

IBS construction must adhere to building codes and regulations governing off-site manufacturing and assembly processes. Addressing regulatory challenges and ensuring compliance is crucial for the successful implementation of IBS projects.

7.2 Skilled Workforce

The transition to IBS construction requires a skilled workforce proficient in new technologies and methodologies. Training and upskilling workers to adapt to the changing construction landscape is essential for realizing the full potential of IBS.

7.3 Logistics and Transportation

Efficient logistics and transportation are critical for the success of IBS projects. The transportation of large prefabricated components from manufacturing facilities to the construction site requires careful planning and coordination.

8. The Future of IBS Construction

The future of IBS construction is promising, with ongoing technological advancements and growing industry acceptance. Key areas of development that will shape the future of IBS construction include:

- Continued integration of automation and robotics

- Advancements in sustainable materials and construction practices

- Enhanced interoperability between BIM and IBS systems

- Collaboration among stakeholders to establish standardized IBS practices

9. Conclusion

IBS construction represents a transformative shift in the construction industry. With its numerous benefits, technological advancements, and sustainable practices, IBS has the potential to revolutionize the way buildings are designed, constructed, and managed. Embracing IBS construction will lead to improved efficiency, quality, and environmental stewardship.

FAQs

- What is IBS construction?

- IBS construction refers to an approach that utilizes off-site manufacturing and assembly processes to enhance efficiency, quality, and sustainability in construction projects.

- What are the benefits of IBS construction?

- IBS construction offers benefits such as speed and efficiency, improved quality and consistency, cost savings, safety improvements, and sustainability.

- How do technological advancements contribute to IBS construction?

- Technological advancements like 3D printing, augmented reality, IoT, AI, and advanced materials enhance the capabilities of IBS construction, enabling greater customization, efficiency, and productivity.

- What challenges does IBS construction face?

- Challenges in IBS construction include regulatory compliance, the need for a skilled workforce, and efficient logistics and transportation of prefabricated components.

- What does the future hold for IBS construction?

- The future of IBS construction is characterized by further integration of automation and robotics, advancements in sustainable materials, improved interoperability with BIM, and collaboration among stakeholders to establish standardized practices.

This article provides an in-depth exploration of the future of IBS construction, highlighting its benefits, technological advancements, challenges, and the potential it holds for transforming the construction industry. By embracing innovations in IBS construction, the industry can strive towards faster, more cost-effective, and sustainable building practices.