Blog

Navigating IBS Construction Regulations in Malaysia

Navigating IBS Construction Regulations in Malaysia

Table of Contents

- Introduction to IBS Construction

- Advantages of IBS Construction in Malaysia

- IBS Construction Regulations and Standards in Malaysia

- Compliance and Approval Process for IBS Projects

- IBS Components and Systems

- 5.1 Precast Concrete

- 5.2 Steel Framing

- 5.3 Modular Construction

- 5.4 Panel Systems

- Roles and Responsibilities of Stakeholders in IBS Construction

- 6.1 Developers

- 6.2 Architects and Engineers

- 6.3 Contractors

- 6.4 Manufacturers

- 6.5 Regulatory Bodies

- Training and Capacity Building for IBS in Malaysia

- Funding and Incentives for IBS Adoption

- Challenges and Potential Solutions in Implementing IBS Construction

- Case Studies of Successful IBS Projects in Malaysia

- Future Trends in IBS Construction

- Conclusion

- FAQs (Frequently Asked Questions)

1. Introduction to IBS Construction

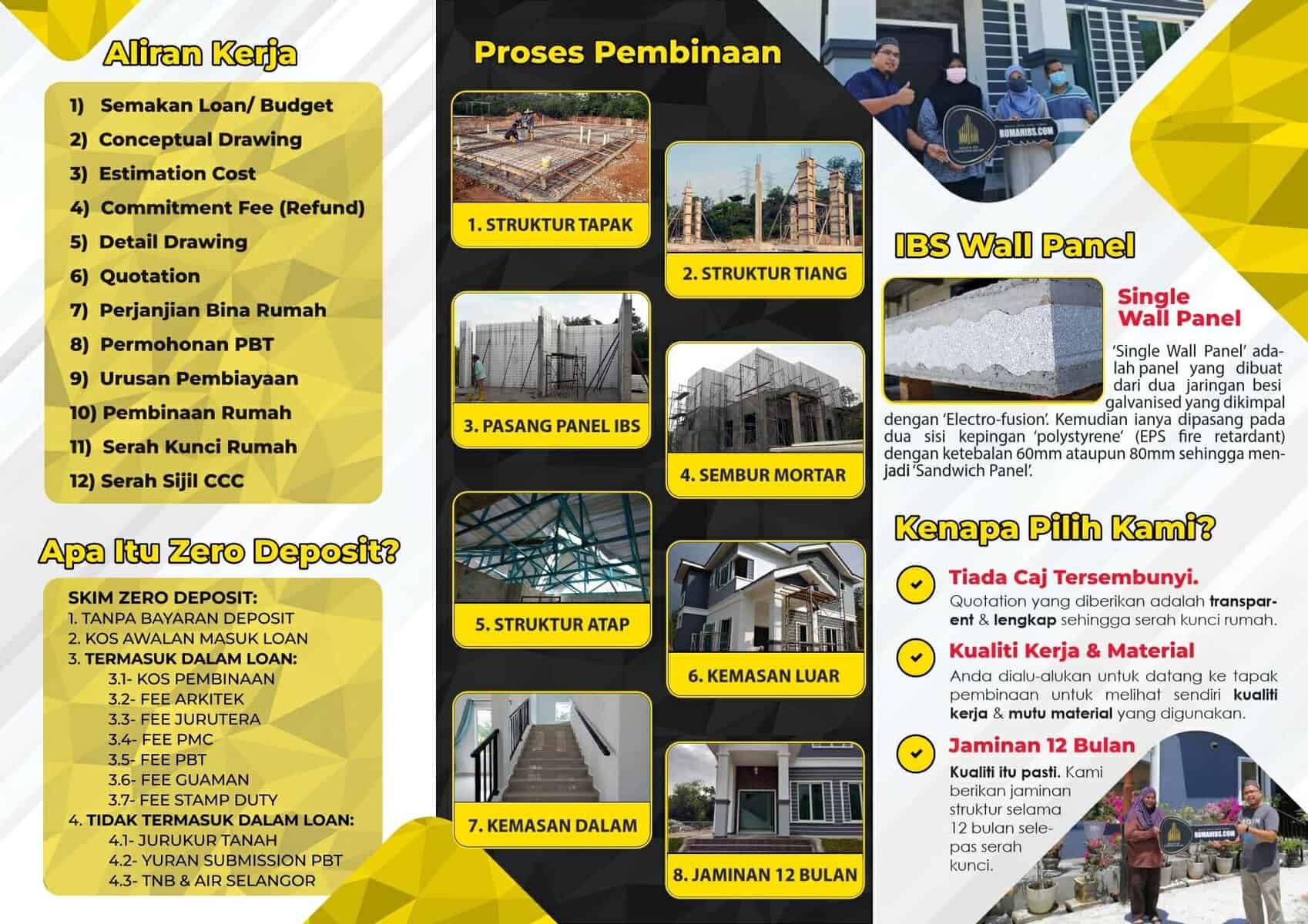

The construction industry in Malaysia has witnessed significant advancements in recent years, particularly with the adoption of Industrialized Building System (IBS) techniques. IBS involves the use of prefabricated components and off-site construction methods to enhance efficiency, productivity, and building quality. This article explores the regulations and practices associated with IBS construction in Malaysia, providing valuable insights for industry stakeholders.

2. Advantages of IBS Construction in Malaysia

IBS construction offers numerous advantages that address the challenges faced by the construction industry in Malaysia. This section discusses the benefits of IBS, including reduced construction time, improved quality control, cost savings, enhanced safety, and sustainable practices. By leveraging these advantages, Malaysia aims to boost productivity and meet the demands of its growing construction sector.

3. IBS Construction Regulations and Standards in Malaysia

To ensure the successful implementation of IBS in Malaysia, stringent regulations and standards have been established. This section outlines the key regulations governing IBS construction, covering aspects such as design, manufacturing, transportation, installation, and maintenance. By adhering to these regulations, stakeholders can ensure the safety, durability, and quality of IBS structures.

4. Compliance and Approval Process for IBS Projects

Stakeholders involved in IBS construction projects must navigate the compliance and approval process set by the relevant authorities in Malaysia. This section provides an overview of the process, including the submission of detailed plans, obtaining necessary approvals, and undergoing inspections. Compliance with these processes is vital to prevent delays, penalties, and potential project suspensions.

5. IBS Components and Systems

IBS encompasses a wide range of components and systems that contribute to efficient and sustainable construction. This section delves into the various types of IBS components, including precast concrete, steel framing, modular construction, and panel systems. Each component has its own advantages and considerations, and the selection depends on project requirements, cost-effectiveness, and construction timelines.

5.1 Precast Concrete

Precast concrete is a commonly used IBS component known for its durability and versatility. This sub-topic explores the benefits of precast concrete in Malaysia, including reduced construction time, enhanced quality control, and improved site safety. It also discusses the challenges associated with the manufacturing, transportation, and installation of precast concrete elements.

5.2 Steel Framing

Steel framing is another popular choice in IBS construction, offering strength, flexibility, and sustainability. This sub-topic explores the advantages of steel framing, such as its lightweight nature, ease of installation, and resistance to fire and pests. It also highlights the considerations for design, fabrication, and erection of steel-framed structures in compliance with regulations.

5.3 Modular Construction

Modular construction involves the assembly of prefabricated modules to create complete building structures. This sub-topic examines the benefits of modular construction in Malaysia, including accelerated project timelines, reduced on-site labor requirements, and enhanced quality control. It also addresses the challenges related to module transportation, integration, and site assembly.

5.4 Panel Systems

Panel systems, such as insulated concrete panels or sandwich panels, offer efficient construction solutions for walls, floors, and roofs. This sub-topic explores the advantages of panel systems, including thermal and acoustic insulation properties, speedy installation, and design flexibility. It also covers considerations for panel manufacturing, handling, and installation in compliance with regulations.

6. Roles and Responsibilities of Stakeholders in IBS Construction

The successful implementation of IBS construction in Malaysia relies on the collaboration of various stakeholders. This section explores the roles and responsibilities of key stakeholders, including developers, architects and engineers, contractors, manufacturers, and regulatory bodies.

6.1 Developers

Developers play a crucial role in driving the adoption of IBS by recognizing its benefits and integrating it into their project plans. This sub-topic discusses the responsibilities of developers in selecting suitable IBS components, engaging qualified professionals, and ensuring compliance with regulations throughout the construction process.

6.2 Architects and Engineers

Architects and engineers are instrumental in designing IBS-compliant structures that meet safety, functionality, and aesthetic requirements. This sub-topic explores the considerations and best practices for architects and engineers in incorporating IBS into their designs, collaborating with manufacturers, and overseeing the construction process.

6.3 Contractors

Contractors are responsible for executing the construction process and coordinating various activities on-site. This sub-topic discusses the roles of contractors in managing IBS projects, including procurement of IBS components, logistics planning, on-site assembly, and quality control measures.

6.4 Manufacturers

Manufacturers of IBS components play a vital role in delivering high-quality, standardized elements for construction projects. This sub-topic examines the responsibilities of manufacturers in ensuring compliance with regulations, maintaining consistent production standards, and supporting the integration of IBS into the construction supply chain.

6.5 Regulatory Bodies

Regulatory bodies in Malaysia oversee the implementation and compliance of IBS construction regulations. This sub-topic highlights the role of regulatory bodies in establishing guidelines, conducting inspections, certifying IBS components, and promoting the adoption of IBS practices through training and capacity-building initiatives.

7. Training and Capacity Building for IBS in Malaysia

To support the adoption of IBS in Malaysia, training and capacity-building programs are crucial. This section explores the initiatives aimed at enhancing the knowledge and skills of industry professionals in IBS design, manufacturing, construction, and quality assurance. It also discusses the importance of promoting safety practices, quality control measures, and sustainable approaches within the IBS framework.

8. Funding and Incentives for IBS Adoption

To encourage the widespread adoption of IBS in Malaysia, various funding schemes and incentives are available. This section provides an overview of the financial support options, including grants, tax incentives, and low-interest loans. It highlights the eligibility criteria and application processes for stakeholders seeking financial assistance to implement IBS projects.

9. Challenges and Potential Solutions in Implementing IBS Construction

While IBS brings numerous benefits, its implementation also presents challenges. This section addresses the common challenges faced by stakeholders in adopting IBS, such as resistance to change, limited awareness, supply chain capacity, and technological barriers. It also explores potential solutions and strategies to overcome these challenges, emphasizing the importance of collaboration and continuous improvement.

10. Case Studies of Successful IBS Projects in Malaysia

Examining successful IBS projects provides valuable insights into the practical application and benefits of IBS construction in Malaysia. This section presents case studies that highlight exemplary projects across different sectors, showcasing the positive impact of IBS in terms of cost savings, construction efficiency, building quality, and sustainability.

11. Future Trends in IBS Construction

As the construction industry continues to evolve, new trends and innovations emerge within the field of IBS construction. This section explores future trends, including the integration of Building Information Modeling (BIM), automation, robotics, digitalization, and the adoption of smart technologies. It discusses how these advancements will further enhance the efficiency, sustainability, and productivity of IBS projects in Malaysia.

12. Conclusion

The implementation of IBS construction regulations in Malaysia has revolutionized the industry by offering numerous advantages in terms of efficiency, quality, and sustainability. By navigating these regulations, complying with standards, and fostering collaboration among stakeholders, the construction sector can embrace IBS as a key driver of progress and development.

FAQs (Frequently Asked Questions)

Q1: What is IBS construction, and why is it important in Malaysia? IBS construction involves the use of prefabricated components and off-site construction methods. It is important in Malaysia as it addresses challenges such as labor shortages, increased construction costs, and the need for sustainable practices, thereby improving productivity and quality in the construction sector.

Q2: What are the benefits of IBS construction in Malaysia? IBS construction offers benefits such as reduced construction time, improved quality control, cost savings, enhanced safety, and sustainable practices. These advantages contribute to the growth and efficiency of the Malaysian construction industry.

Q3: What are the compliance and approval processes for IBS projects in Malaysia? Compliance and approval processes for IBS projects in Malaysia involve submitting detailed plans, obtaining necessary approvals, and undergoing inspections to ensure adherence to regulations and standards. Compliance is essential to ensure the safety, durability, and quality of IBS structures.

Q4: What are the future trends in IBS construction in Malaysia? The future trends in IBS construction in Malaysia include the integration of Building Information Modeling (BIM), automation, robotics, digitalization, and the adoption of smart technologies. These advancements will further enhance the efficiency, sustainability, and productivity of IBS projects.

Q5: Are there funding opportunities available for IBS adoption in Malaysia? Yes, Malaysia provides funding schemes, grants, and incentives to support developers, contractors, and manufacturers in adopting IBS construction methods. These financial incentives aim to offset the initial investment and promote long-term benefits.

In conclusion, navigating IBS construction regulations in Malaysia is essential for stakeholders in the industry. By understanding the benefits, complying with regulations, and fostering collaboration, the construction sector can harness the advantages of IBS to drive progress, improve efficiency, and contribute to sustainable development.