Blog

Panelised Construction: The Future of IBS in Malaysia

Panelised Construction: The Future of IBS in Malaysia

Table of Contents

- Introduction

- Understanding Panelised Construction

- Definition and Process

- Types of Panels Used

- Advantages of Panelised Construction

- Enhanced Efficiency and Speed

- Cost Savings

- Improved Quality and Safety

- Sustainable Construction Practices

- Current Applications of Panelised Construction in Malaysia

- Residential Buildings

- Commercial and Industrial Structures

- Infrastructure Projects

- Challenges and Limitations of Panelised Construction

- Skilled Labor and Expertise

- Design Flexibility

- Transportation and Logistics

- The Future of IBS in Malaysia

- Government Initiatives and Support

- Research and Development Efforts

- Adoption by the Construction Industry

- The Benefits of Panelised Construction for Sustainable Development

- Energy Efficiency

- Reduced Carbon Footprint

- Waste Reduction and Recycling

- Conclusion

- FAQs (Frequently Asked Questions)

Introduction

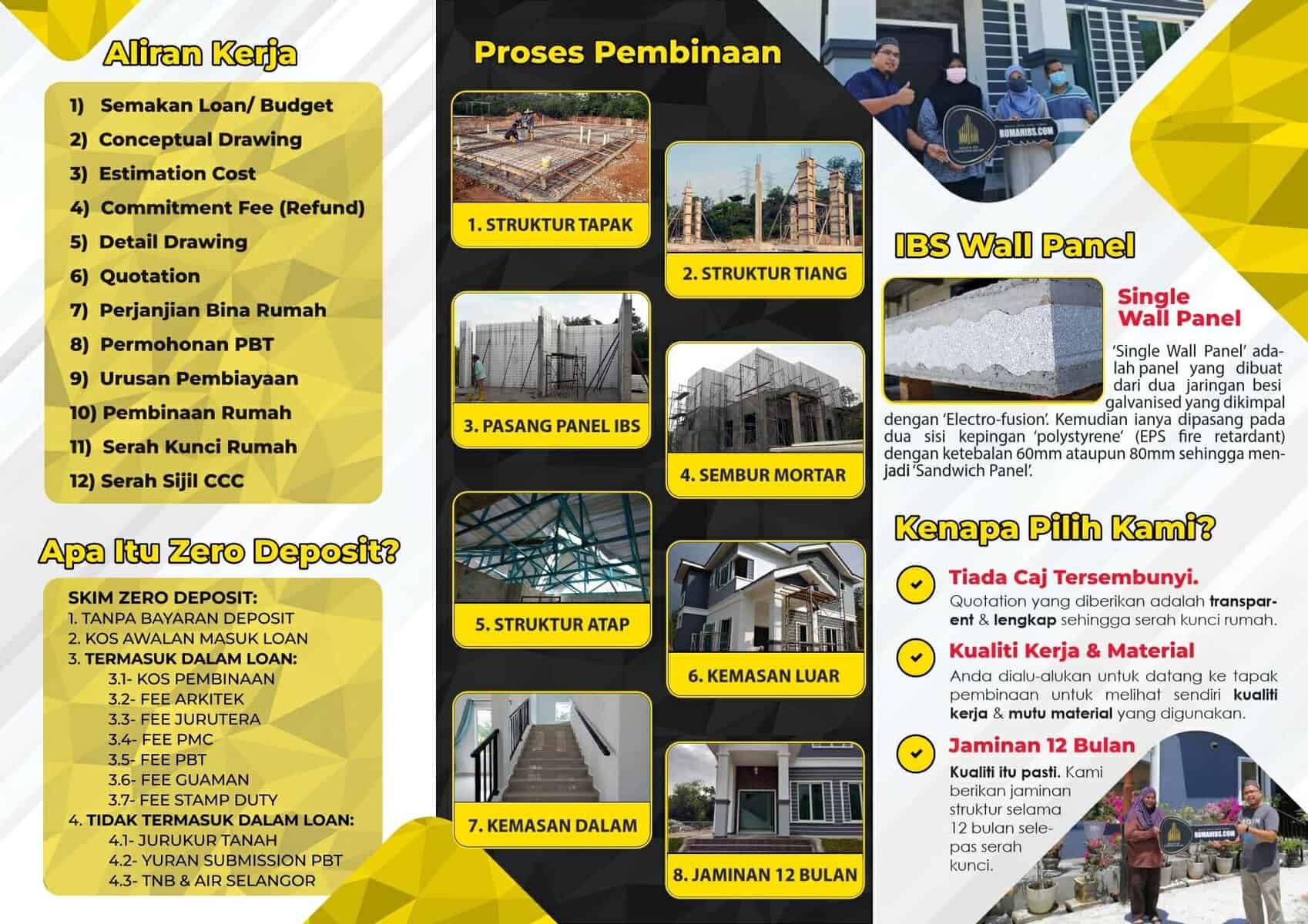

Panelised construction, also known as Industrialized Building System (IBS), is revolutionizing the construction industry in Malaysia. This innovative method involves the use of prefabricated panels that are manufactured off-site and then assembled on-site, offering numerous advantages over traditional construction methods. In this article, we will explore the concept of panelised construction, its benefits, current applications, challenges, and its potential to shape the future of the construction industry in Malaysia.

Understanding Panelised Construction

Definition and Process

Panelised construction refers to a building system that utilizes prefabricated panels, which are produced off-site in a controlled environment. These panels are then transported to the construction site and assembled to form the structure. The process involves precise manufacturing, including cutting, shaping, and assembling various components of the building, such as walls, floors, and roofs.

Types of Panels Used

There are various types of panels used in panelised construction, including:

- Structural Insulated Panels (SIPs): These panels consist of two outer layers and a core material, offering excellent thermal insulation and structural strength.

- Timber-based Panels: Made from engineered wood products, these panels provide flexibility in design and construction while maintaining structural integrity.

- Concrete Panels: Constructed using precast concrete, these panels offer durability, fire resistance, and high load-bearing capacity.

Advantages of Panelised Construction

Panelised construction offers several advantages over traditional construction methods:

Enhanced Efficiency and Speed

By using prefabricated panels, the construction process becomes highly efficient. The off-site manufacturing enables simultaneous work on different components, reducing construction time significantly. Additionally, the precise manufacturing ensures minimal errors and rework, leading to faster project completion.

Cost Savings

Panelised construction can result in cost savings throughout the construction process. The controlled manufacturing environment reduces material waste, and the efficient assembly process minimizes labor costs. Moreover, the faster construction timeline reduces financing expenses and enables earlier occupancy or utilization of the building.

Improved Quality and Safety

The controlled manufacturing process of panelised construction ensures high-quality components that meet stringent standards. The panels undergo rigorous testing, resulting in better structural integrity and improved building performance. Additionally, the reduced on-site construction activities minimize safety hazards and the associated risks for workers.

Sustainable Construction Practices

Panelised construction promotes sustainability in the building industry. The precise manufacturing process reduces material waste and energy consumption. Furthermore, the use of eco-friendly materials, such as recycled steel or timber, and the integration of energy-efficient features contribute to environmentally friendly construction practices.

Current Applications of Panelised Construction in Malaysia

Panelised construction has gained traction in various construction projects across Malaysia:

Residential Buildings

In the residential sector, panelised construction has been widely utilized for affordable housing projects. The efficient construction process helps address the increasing demand for housing while maintaining affordability and quality. This method has enabled the construction of housing units in shorter timeframes, benefiting both developers and homeowners.

Commercial and Industrial Structures

Panelised construction has also found applications in the construction of commercial and industrial buildings. The streamlined construction process allows for faster completion of projects, enabling businesses to commence operations sooner. Moreover, the flexibility in design and customization of panels caters to specific requirements of commercial and industrial spaces.

Infrastructure Projects

IBS has been incorporated into infrastructure projects, including bridges, schools, and hospitals. The use of precast panels enhances the durability and structural integrity of these projects. Additionally, the reduced disruption to traffic during construction minimizes inconvenience to the public.

Challenges and Limitations of Panelised Construction

Despite its advantages, panelised construction faces certain challenges and limitations:

Skilled Labor and Expertise

Panelised construction requires skilled labor to handle the manufacturing and on-site assembly processes. Acquiring and retaining a skilled workforce can be a challenge, as it requires specialized training and expertise. Addressing this issue requires investments in training programs and collaboration between industry stakeholders and educational institutions.

Design Flexibility

While panelised construction offers many design possibilities, there may be limitations in achieving complex architectural designs or non-standard building shapes. The standardized nature of panels can restrict design flexibility, requiring careful planning and coordination during the design phase.

Transportation and Logistics

The transportation of large panels from the manufacturing facility to the construction site poses logistical challenges. Specialized vehicles and equipment are needed to ensure the safe and timely delivery of panels. Proper coordination between manufacturers, logistics providers, and construction teams is essential to overcome these challenges.

The Future of IBS in Malaysia

The future of panelised construction in Malaysia looks promising, driven by various factors:

Government Initiatives and Support

The Malaysian government has recognized the potential of IBS and has implemented initiatives to promote its adoption. These initiatives include financial incentives, policy support, and the establishment of research and development centers to enhance IBS capabilities in the country.

Research and Development Efforts

Continuous research and development efforts are crucial to further improve panelised construction techniques and materials. Collaborative projects between industry players, research institutions, and universities aim to develop innovative solutions, enhance design possibilities, and address challenges associated with panelised construction.

Adoption by the Construction Industry

As more successful projects are completed using panelised construction, the industry’s confidence in the method continues to grow. Construction companies are increasingly embracing IBS and integrating it into their project workflows. With growing expertise and experience, panelised construction will become more mainstream in Malaysia’s construction industry.

The Benefits of Panelised Construction for Sustainable Development

Panelised construction contributes significantly to sustainable development:

Energy Efficiency

The precise manufacturing of panels ensures better insulation and energy efficiency in buildings, reducing the overall energy consumption and carbon footprint.

Reduced Carbon Footprint

Panelised construction reduces construction waste and carbon emissions compared to traditional construction methods, promoting a greener environment.

Waste Reduction and Recycling

The controlled manufacturing process minimizes material waste, and the use of eco-friendly materials promotes recycling and reduces the depletion of natural resources.

Conclusion

Panelised construction, or IBS, is transforming the construction landscape in Malaysia. Its ability to enhance efficiency, reduce costs, improve quality and safety, and promote sustainable practices positions it as the future of construction in the country. With the support of the government, ongoing research and development, and increasing adoption by the industry, panelised construction is set to revolutionize the way buildings are constructed in Malaysia.

FAQs (Frequently Asked Questions)

- Is panelised construction more expensive than traditional construction methods? Panelised construction can result in cost savings due to reduced labor and construction time, offsetting the initial investment in manufacturing and transportation of panels.

- Does panelised construction compromise architectural design possibilities? While panelised construction offers design flexibility, achieving complex architectural designs may require careful planning and coordination during the design phase.

- Is panelised construction environmentally friendly? Yes, panelised construction promotes sustainability through reduced material waste, energy-efficient features, and the use of eco-friendly materials.

- Are there any specific regulations or standards for panelised construction in Malaysia? Yes, Malaysia has established regulations and standards for panelised construction to ensure quality, safety, and compliance with building codes.

-

What are the key advantages of panelised construction for infrastructure projects? Panelised construction enhances the durability and structural integrity of infrastructure projects while minimizing disruption to traffic during construction.