Blog

Pembinaan Panelisasi: Masa Depan Sistem Pembinaan Berindustri (IBS) di Malaysia

Pembinaan Panelisasi: Masa Depan Sistem Pembinaan Berindustri (IBS) di Malaysia

Kandungan

- Pendahuluan

- Memahami Pembinaan Panelisasi

- Definisi dan Proses

- Jenis Panel yang Digunakan

- Kelebihan Pembinaan Panelisasi

- Efisiensi dan Kelajuan Meningkat

- Penjimatan Kos

- Kualiti dan Keselamatan yang Lebih Baik

- Amalan Pembinaan Mampan

- Aplikasi Semasa Pembinaan Panelisasi di Malaysia

- Bangunan Perumahan

- Struktur Komersial dan Industri

- Projek Infrastruktur

- Cabaran dan Had Pembinaan Panelisasi

- Tenaga Kerja dan Kecekapan Kemahiran

- Fleksibiliti Reka Bentuk

- Pengangkutan dan Logistik

- Masa Depan IBS di Malaysia

- Inisiatif dan Sokongan Kerajaan

- Usaha Penyelidikan dan Pembangunan

- Penerimaan oleh Industri Pembinaan

- Manfaat Pembinaan Panelisasi untuk Pembangunan Mampan

- Kecekapan Tenaga

- Jejak Karbon yang Dikurangkan

- Pengurangan dan Kitar Semula Sisa

- Kesimpulan

- Soalan Lazim (FAQs)

Pendahuluan

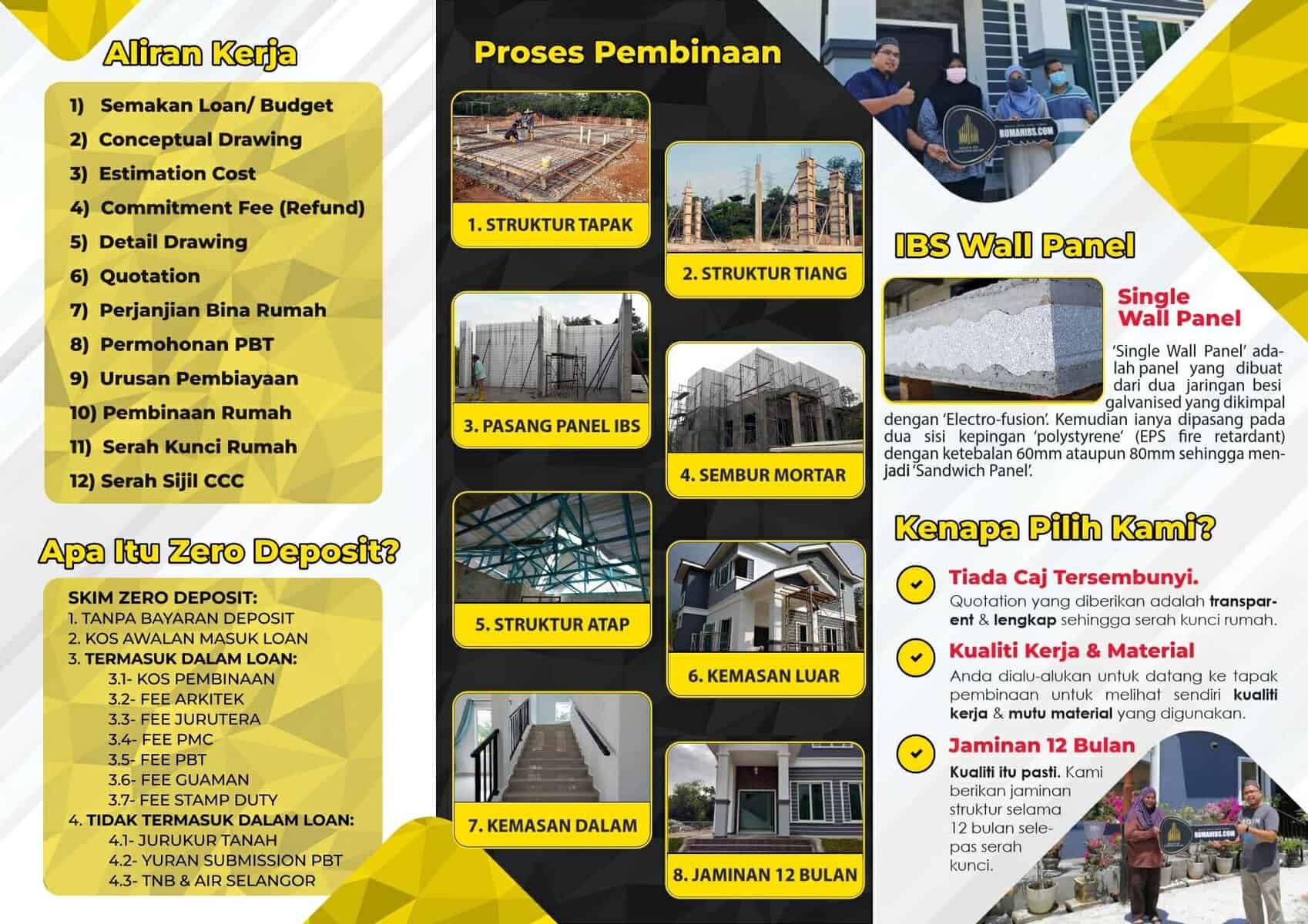

Pembinaan panelisasi, juga dikenali sebagai Sistem Pembinaan Berindustri (IBS), sedang mengubah landskap industri pembinaan di Malaysia. Kaedah inovatif ini melibatkan penggunaan panel pra-fabrikasi yang dihasilkan di luar tapak dan kemudian dipasang di tapak pembinaan, menawarkan pelbagai kelebihan berbanding dengan kaedah pembinaan tradisional. Dalam artikel ini, kita akan meneroka konsep pembinaan panelisasi, kelebihannya, aplikasi semasa, cabaran, dan potensinya untuk membentuk masa depan industri pembinaan di Malaysia.

Memahami Pembinaan Panelisasi

Definisi dan Proses

Pembinaan panelisasi merujuk kepada sistem pembinaan yang menggunakan panel pra-fabrikasi yang dihasilkan di luar tapak dalam persekitaran yang terkawal. Panel-panel ini kemudian diangkut ke tapak pembinaan dan dipasang untuk membentuk struktur bangunan. Proses ini melibatkan pembuatan yang tepat, termasuk pemotongan, membentuk, dan menyusun komponen-komponen bangunan seperti dinding, lantai, dan bumbung.

Jenis Panel yang Digunakan

Terdapat pelbagai jenis panel yang digunakan dalam pembinaan panelisasi, antaranya:

- Panel Bersekat Berstruktur (SIP): Panel ini terdiri daripada dua lapisan luar dan bahan teras, menawarkan kebolehan isolasi termal yang baik dan kekuatan struktur yang tinggi.

- Panel Berasaskan Kayu: Diperbuat daripada produk kayu yang dihasilkan secara berkejur, panel ini memberikan fleksibiliti dalam reka bentuk dan pembinaan sambil memastikan integriti struktur.

- Panel Konkrit: Dibina menggunakan konkrit pra-corak, panel ini menawarkan kebolehan tahan lama, kebal api, dan keupayaan pemikul beban yang tinggi.

Kelebihan Pembinaan Panelisasi

Pembinaan panelisasi menawarkan beberapa kelebihan berbanding dengan kaedah pembinaan tradisional:

Efisiensi dan Kelajuan Meningkat

Dengan menggunakan panel pra-fabrikasi, proses pembinaan menjadi lebih efisien. Pengeluaran di luar tapak membolehkan kerja serentak pada komponen-komponen yang berbeza, mengurangkan masa pembinaan secara ketara. Selain itu, pembuatan yang tepat memastikan kesilapan dan kerja ulang yang minima, menjurus kepada penyelesaian projek yang lebih cepat.

Penjimatan Kos

Pembinaan panelisasi boleh membawa penjimatan kos sepanjang proses pembinaan. Persekitaran pembuatan yang terkawal mengurangkan pembaziran bahan, dan proses penyusunan yang cekap mengurangkan kos buruh. Tambahan pula, jangka waktu pembinaan yang lebih cepat mengurangkan kos pembiayaan dan membolehkan pemilik bangunan menduduki atau menggunakan bangunan tersebut lebih awal.

Kualiti dan Keselamatan yang Lebih Baik

Proses pembuatan yang terkawal dalam pembinaan panelisasi memastikan komponen berkualiti tinggi yang mematuhi piawai yang ketat. Panel-panel ini menjalani ujian yang ketat, menghasilkan integriti struktur yang lebih baik dan prestasi bangunan yang meningkat. Selain itu, pengurangan aktiviti pembinaan di tapak mengurangkan risiko keselamatan dan bahaya untuk pekerja.

Amalan Pembinaan Mampan

Pembinaan panelisasi menggalakkan kelestarian dalam industri pembinaan. Proses pembuatan yang tepat mengurangkan pembaziran bahan dan penggunaan tenaga. Selain itu, penggunaan bahan mesra alam seperti keluli kitar semula atau kayu, serta pengintegrasian ciri-ciri penjimatan tenaga, menyumbang kepada amalan pembinaan yang mesra alam.

Aplikasi Semasa Pembinaan Panelisasi di Malaysia

Pembinaan panelisasi telah mendapat perhatian dalam pelbagai projek pembinaan di Malaysia:

Bangunan Perumahan

Dalam sektor perumahan, pembinaan panelisasi telah digunakan secara meluas untuk projek perumahan yang terjangkau. Proses pembinaan yang efisien membantu menangani permintaan perumahan yang meningkat sambil mengekalkan harga yang terjangkau dan kualiti yang baik. Kaedah ini membolehkan pembinaan unit perumahan dalam jangka masa yang lebih singkat, memberi manfaat kepada pembangun dan pemilik rumah.

Struktur Komersial dan Industri

Pembinaan panelisasi juga digunakan dalam pembinaan bangunan komersial dan industri. Proses pembinaan yang lancar membolehkan projek selesai dengan lebih cepat, membolehkan perniagaan memulakan operasi lebih awal. Selain itu, fleksibiliti dalam reka bentuk dan penyesuaian panel memenuhi keperluan khusus ruang komersial dan industri.

Projek Infrastruktur

IBS telah diintegrasikan dalam projek infrastruktur termasuk jambatan, sekolah, dan hospital. Penggunaan panel pra-corak meningkatkan ketahanan dan integriti struktur projek-projek ini. Selain itu, gangguan kepada trafik semasa pembinaan dikurangkan, mengurangkan kesulitan kepada orang awam.

Cabaran dan Had Pembinaan Panelisasi

Walaupun memiliki kelebihan, pembinaan panelisasi juga menghadapi cabaran dan had tertentu:

Tenaga Kerja dan Kecekapan Kemahiran

Pembinaan panelisasi memerlukan tenaga kerja mahir untuk mengendalikan proses pembuatan dan pemasangan di tapak. Membekalkan dan mengekalkan tenaga kerja yang mahir boleh menjadi cabaran, memerlukan latihan khusus dan kepakaran. Menangani isu ini memerlukan pelaburan dalam program latihan dan kerjasama antara pemangku industri dan institusi pendidikan.

Fleksibiliti Reka Bentuk

Walaupun pembinaan panelisasi menawarkan pelbagai kemungkinan reka bentuk, terdapat had dalam mencapai reka bentuk seni bina yang kompleks atau bentuk bangunan bukan standard. Sifat piawai panel boleh menghadkan fleksibiliti reka bentuk, memerlukan perancangan dan koordinasi yang teliti semasa fasa reka bentuk.

Pengangkutan dan Logistik

Pengangkutan panel-panel yang besar dari kilang pengeluaran ke tapak pembinaan membawa cabaran logistik. Kenderaan dan peralatan khusus diperlukan untuk memastikan penghantaran panel berlaku dengan selamat dan tepat pada masanya. Koordinasi yang baik antara pengeluar, pembekal logistik, dan pasukan pembinaan adalah penting untuk mengatasi cabaran ini.

Masa Depan IBS di Malaysia

Masa depan pembinaan panelisasi di Malaysia menunjukkan kecemerlangan, didorong oleh beberapa faktor:

Inisiatif dan Sokongan Kerajaan

Kerajaan Malaysia telah mengiktiraf potensi IBS dan telah melaksanakan inisiatif untuk mempromosikan penerimaannya. Inisiatif-inisiatif ini termasuk insentif kewangan, sokongan dasar, dan penubuhan pusat penyelidikan dan pembangunan untuk meningkatkan keupayaan IBS di negara ini.

Usaha Penyelidikan dan Pembangunan

Usaha penyelidikan dan pembangunan yang berterusan adalah penting untuk meningkatkan teknik dan bahan pembinaan panelisasi. Projek-projek kolaboratif antara pemain industri, institusi penyelidikan, dan universiti bertujuan untuk mengembangkan penyelesaian inovatif, meningkatkan kemungkinan reka bentuk, dan menangani cabaran yang berkaitan dengan pembinaan panelisasi.

Penerimaan oleh Industri Pembinaan

Semakin banyak projek yang berjaya diselesaikan menggunakan pembinaan panelisasi, keyakinan industri terhadap kaedah ini terus meningkat. Syarikat pembinaan semakin menerima IBS dan mengintegrasikannya ke dalam alur kerja projek mereka. Dengan pengalaman dan kepakaran yang semakin berkembang, pembinaan panelisasi akan menjadi lebih meluas di industri pembinaan Malaysia.

Manfaat Pembinaan Panelisasi untuk Pembangunan Mampan

Pembinaan panelisasi memberikan sumbangan yang besar kepada pembangunan mampan:

Kecekapan Tenaga

Pembuatan panel yang tepat memastikan penyejukan dan penjimatan tenaga yang lebih baik dalam bangunan, mengurangkan penggunaan tenaga keseluruhan dan jejak karbon.

Jejak Karbon yang Dikurangkan

Pembinaan panelisasi mengurangkan pembaziran bahan pembinaan dan pelepasan karbon berbanding dengan kaedah pembinaan tradisional, mendorong alam sekitar yang lebih hijau.

Pengurangan dan Kitar Semula Sisa

Proses pembuatan yang terkawal mengurangkan pembaziran bahan, dan penggunaan bahan mesra alam menyumbang kepada pengitaran semula dan pengurangan sisa, mengurangkan pengekalan sumber semula jadi.

Kesimpulan

Pembinaan panelisasi, atau IBS, sedang mengubah landskap pembinaan di Malaysia. Keupayaannya untuk meningkatkan efisiensi, mengekalkan penjimatan kos, meningkatkan kualiti dan keselamatan, serta mempromosikan amalan pembinaan mampan menjadikannya sebagai masa depan pembinaan di negara ini. Dengan sokongan kerajaan, usaha penyelidikan dan pembangunan yang berterusan, serta peningkatan penerimaan oleh industri, pembinaan panelisasi akan mengubah cara bangunan dibina di Malaysia.

Soalan Lazim (FAQs)

- Adakah pembinaan panelisasi lebih mahal daripada kaedah pembinaan tradisional? Pembinaan panelisasi dapat menjimatkan kos melalui pengurangan buruh dan masa pembinaan, mengimbangi pelaburan awal dalam pembuatan dan pengangkutan panel.

- Adakah pembinaan panelisasi menghadkan kemungkinan reka bentuk seni bina? Walaupun pembinaan panelisasi menawarkan fleksibiliti reka bentuk, mencapai reka bentuk seni bina yang kompleks mungkin memerlukan perancangan dan koordinasi yang teliti semasa fasa reka bentuk.

- Adakah pembinaan panelisasi mesra alam? Ya, pembinaan panelisasi menggalakkan pembangunan mampan melalui pengurangan pembaziran bahan, ciri-ciri penjimatan tenaga, dan penggunaan bahan mesra alam.

- Adakah terdapat peraturan atau piawai khusus untuk pembinaan panelisasi di Malaysia? Ya, Malaysia telah menetapkan peraturan dan piawai khusus untuk pembinaan panelisasi bagi memastikan kualiti, keselamatan, dan pematuhan dengan kod bangunan.

- Apakah kelebihan utama pembinaan panelisasi untuk projek infrastruktur? Pembinaan panelisasi meningkatkan ketahanan dan integriti struktur projek infrastruktur sambil mengurangkan gangguan kepada trafik semasa pembinaan.