Blog

Selecting High-Quality Materials for IBS Construction

Selecting High-Quality Materials for IBS Construction

Table of Contents

- Introduction to IBS Construction

- Importance of High-Quality Materials in IBS

- Foundation Materials for IBS

- Concrete Mix Design

- Reinforcement Bars

- Geotechnical Investigation and Soil Stabilization

- Structural Materials for IBS

- Structural Steel

- Precast Concrete Panels

- Composite Materials

- Wall Materials for IBS

- Autoclaved Aerated Concrete (AAC) Blocks

- Insulated Concrete Forms (ICF)

- Lightweight Concrete Panels

- Brickwork Systems

- Roofing Materials for IBS

- Metal Roofing

- Concrete Roof Tiles

- Solar Roofing Systems

- Flooring Materials for IBS

- Vinyl Flooring

- Engineered Wood Flooring

- Concrete Flooring

- Ceramic Tiles

- Insulation Materials for IBS

- Polyurethane Foam Insulation

- Mineral Wool Insulation

- Expanded Polystyrene (EPS) Insulation

- Window and Door Materials for IBS

- UPVC Frames

- Aluminum Frames

- Fiberglass Frames

- Finishing Materials for IBS

- Low VOC Paints

- Natural Stone or Ceramic Tiles

- Laminates and Veneers

- Decorative Cladding Systems

- Sustainable Materials for IBS

- Recycled Materials

- Bamboo and Wood Composites

- Green Concrete and Eco-Bricks

- High-Performance Glass

- Cost Considerations for IBS Materials

- Life Cycle Cost Analysis

- Material Efficiency and Waste Reduction

- Bulk Purchasing and Supplier Relationships

- Maintenance and Upkeep of IBS Structures

- Regular Inspections and Repairs

- Cleaning and Surface Maintenance

- Moisture Management and Waterproofing

- Case Studies: Successful IBS Projects

- Residential IBS Projects

- Commercial IBS Projects

- Industrial IBS Projects

- Conclusion

- Frequently Asked Questions (FAQs)

Introduction to IBS Construction

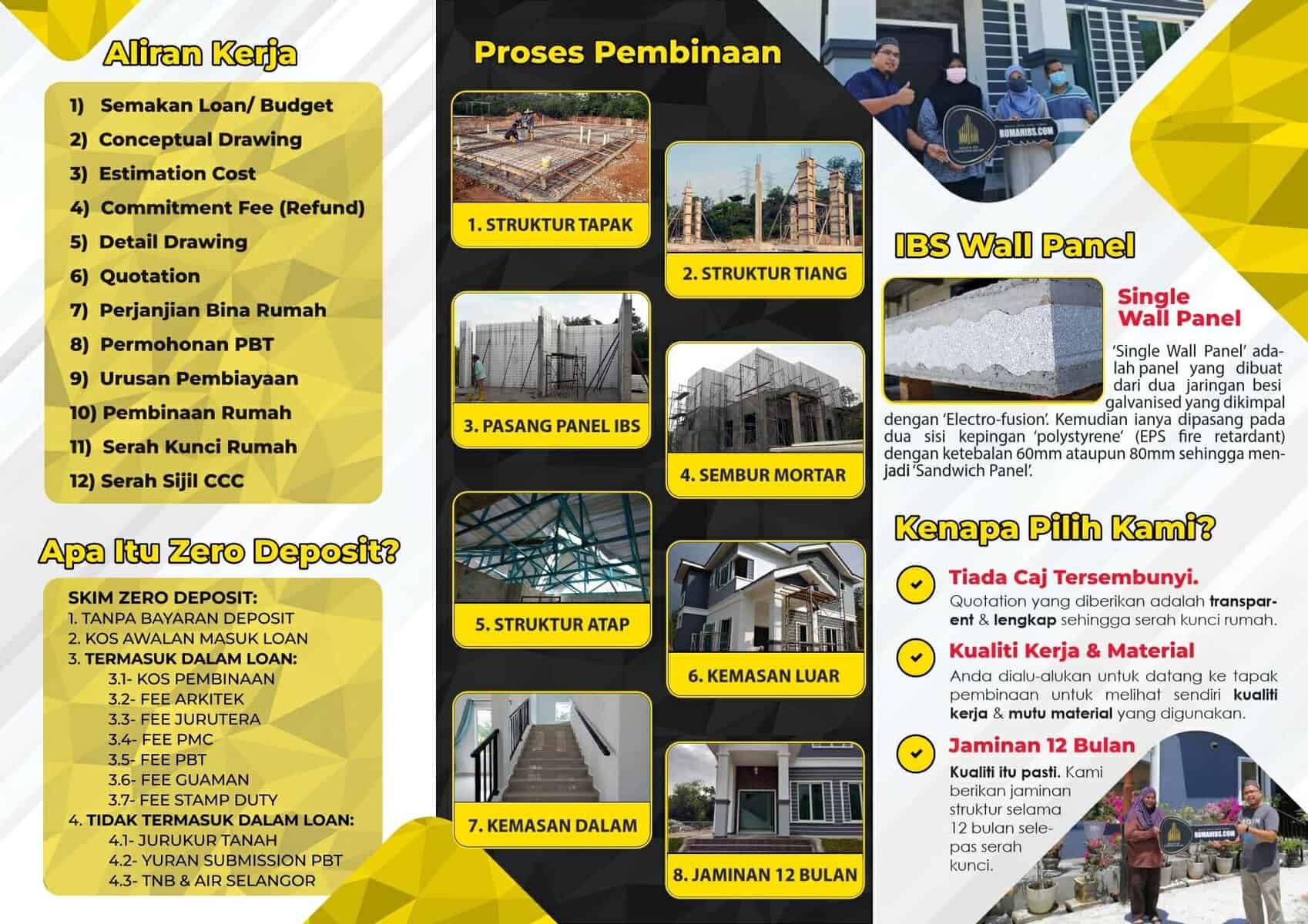

In recent years, the construction industry has witnessed a shift towards more innovative and efficient building methods. Industrialized Building Systems (IBS) have emerged as a viable solution, offering faster construction, improved quality, and reduced environmental impact. The success of an IBS project relies heavily on the selection of high-quality materials that align with the principles of off-site fabrication and efficient assembly.

Importance of High-Quality Materials in IBS

The use of high-quality materials in IBS construction is of utmost importance for several reasons:

- Structural Integrity: High-quality materials ensure the structural stability and durability of IBS buildings. They can withstand the transportation, assembly, and long-term usage associated with off-site construction methods.

- Safety: By using materials that meet stringent quality standards, IBS structures can provide a safe environment for occupants. High-quality materials contribute to the overall safety and stability of the building.

- Efficiency: The efficiency of IBS construction is closely tied to the quality of materials used. High-quality materials facilitate faster and more precise assembly, reducing construction time and labor costs.

- Sustainability: Choosing sustainable materials for IBS construction minimizes environmental impact and promotes long-term sustainability. High-quality, eco-friendly materials contribute to energy efficiency and reduce waste generation.

Foundation Materials for IBS

The foundation is a critical component of any structure, and IBS construction is no exception. The following high-quality materials are commonly used in IBS foundation construction:

Concrete Mix Design

The concrete mix design for IBS foundations should be carefully optimized to meet the specific requirements of the project. It should have adequate strength, workability, and durability to ensure a solid foundation.

Reinforcement Bars

High-quality steel reinforcement bars provide the necessary tensile strength to the foundation. Properly specified and installed reinforcement bars enhance the structural integrity and load-bearing capacity of the foundation.

Geotechnical Investigation and Soil Stabilization

Before foundation construction, a comprehensive geotechnical investigation should be conducted to assess the soil conditions. Based on the findings, appropriate soil stabilization methods can be employed to enhance the foundation’s performance and stability.

Structural Materials for IBS

The structural components of IBS require materials that offer strength, stability, and ease of assembly. Consider the following high-quality materials for IBS structures:

Structural Steel

Structural steel offers exceptional strength and flexibility, making it an ideal choice for IBS construction. Steel components can be prefabricated off-site and easily assembled, resulting in efficient and durable structures.

Precast Concrete Panels

Precast concrete panels are commonly used in IBS construction due to their versatility and ease of installation. They are manufactured off-site under controlled conditions, ensuring high quality and dimensional accuracy.

Composite Materials

Composite materials, such as fiber-reinforced polymers (FRP), offer excellent strength-to-weight ratios and corrosion resistance. They can be custom-engineered to meet specific design requirements, providing innovative solutions for IBS structures.

Wall Materials for IBS

The selection of wall materials for IBS construction affects the thermal performance, acoustic insulation, and overall aesthetics of the building. Consider the following high-quality materials for IBS walls:

Autoclaved Aerated Concrete (AAC) Blocks

AAC blocks are lightweight, yet strong, offering excellent thermal insulation and sound absorption properties. They are easy to handle and contribute to energy-efficient IBS buildings.

Insulated Concrete Forms (ICF)

ICF consists of hollow foam blocks or panels that are filled with concrete. They provide superior thermal insulation and soundproofing capabilities, ensuring comfortable and energy-efficient living spaces.

Lightweight Concrete Panels

Lightweight concrete panels, made with lightweight aggregates and admixtures, offer ease of handling during assembly while providing structural integrity and insulation.

Brickwork Systems

Brickwork systems specifically designed for IBS construction offer the timeless aesthetic appeal of bricks while providing the benefits of efficient off-site fabrication.

Roofing Materials for IBS

Roofing materials for IBS must provide effective weather protection, insulation, and durability. Consider the following high-quality options for IBS roofs:

Metal Roofing

Metal roofing offers durability, fire resistance, and low maintenance. It can be prefabricated off-site and easily installed, reducing construction time. Metal roofs also provide excellent energy efficiency and can be recycled at the end of their lifespan.

Concrete Roof Tiles

Concrete roof tiles are a popular choice for IBS roofs. They offer durability, aesthetics, and a wide range of color options. Concrete tiles provide good insulation and weather resistance, ensuring long-lasting protection for IBS structures.

Solar Roofing Systems

Solar roofing systems integrate photovoltaic (PV) panels into the roof structure, harnessing renewable energy. These systems contribute to energy efficiency and reduce reliance on conventional power sources.

Flooring Materials for IBS

Flooring materials in IBS should be durable, easy to maintain, and visually appealing. Consider the following high-quality materials for IBS floors:

Vinyl Flooring

Vinyl flooring is a versatile and cost-effective option for IBS construction. It is durable, moisture-resistant, and available in a wide range of designs. Vinyl flooring is easy to install and provides excellent performance in high-traffic areas.

Engineered Wood Flooring

Engineered wood flooring combines the beauty of natural wood with enhanced stability and moisture resistance. It is an eco-friendly option and offers excellent performance in IBS structures.

Concrete Flooring

Polished concrete flooring provides a contemporary and durable solution for IBS projects. It offers a sleek and minimalist aesthetic while requiring minimal maintenance.

Ceramic Tiles

Ceramic tiles are a classic choice for IBS flooring. They are available in various designs, colors, and textures, providing versatility and customization options.

Insulation Materials for IBS

Proper insulation is crucial for energy efficiency, thermal comfort, and soundproofing in IBS structures. Consider the following high-quality insulation materials for IBS construction:

Polyurethane Foam Insulation

Polyurethane foam insulation provides excellent thermal insulation and reduces air leakage. It can be applied as spray foam or injected into cavities, ensuring a tight and seamless insulation layer.

Mineral Wool Insulation

Mineral wool insulation is known for its fire resistance and sound absorption properties. It is available in various forms, including batts, blankets, and loose-fill, providing versatility in installation.

Expanded Polystyrene (EPS) Insulation

EPS insulation, commonly known as foam board, offers good thermal insulation and moisture resistance. It is lightweight and easy to handle, making it suitable for IBS construction.

Window and Door Materials for IBS

Windows and doors are essential components of IBS structures, providing natural light, ventilation, and security. Consider the following high-quality materials for IBS windows and doors:

UPVC Frames

UPVC frames are durable, low-maintenance, and offer excellent thermal insulation. They are resistant to rot, corrosion, and termite attacks, making them suitable for IBS construction.

Aluminum Frames

Aluminum frames provide strength, durability, and design versatility. They are lightweight, corrosion-resistant, and can be easily customized to fit specific architectural requirements.

Fiberglass Frames

Fiberglass frames offer superior thermal performance, strength, and durability. They are resistant to warping, expanding, and contracting, making them a reliable choice for IBS structures.

Finishing Materials for IBS

Finishing materials contribute to the aesthetic appeal and ambiance of IBS structures. Consider the following high-quality materials for IBS finishes:

Low VOC Paints

Low VOC (Volatile Organic Compound) paints are environmentally friendly and promote better indoor air quality. They have minimal odor and provide a wide range of color options for IBS interiors.

Natural Stone or Ceramic Tiles

Natural stone or ceramic tiles offer durability, aesthetics, and ease of maintenance. They are available in various sizes, colors, and patterns, allowing for creative design possibilities.

Laminates and Veneers

Laminates and veneers provide an affordable and versatile solution for IBS finishes. They offer a wide range of colors, textures, and patterns, mimicking the look of natural materials.

Decorative Cladding Systems

Decorative cladding systems, such as timber, metal, or composite panels, add visual interest to IBS exteriors. These systems provide durability and weather resistance while enhancing the architectural design.

Sustainable Materials for IBS

Sustainability is a key consideration in modern construction practices. Incorporating sustainable materials in IBS construction reduces the environmental impact and promotes a greener future. Consider the following sustainable materials for IBS:

Recycled Materials

Using recycled materials, such as recycled concrete aggregate or recycled plastic composites, contributes to resource conservation and reduces waste generation.

Bamboo and Wood Composites

Bamboo and wood composites offer sustainable alternatives to traditional timber. These materials are fast-growing, renewable, and have excellent strength and durability properties.

Green Concrete and Eco-Bricks

Green concrete, made with recycled aggregates and supplementary cementitious materials, reduces carbon emissions and promotes resource efficiency. Eco-bricks, made from plastic waste, offer an innovative solution to plastic recycling.

High-Performance Glass

High-performance glass, such as low-emissivity (low-E) glass and insulated glass units (IGUs), improves energy efficiency by reducing heat gain or loss through windows.

Cost Considerations for IBS Materials

While selecting high-quality materials is crucial, it is also essential to consider the cost implications. Here are some cost considerations when choosing materials for IBS construction:

Life Cycle Cost Analysis

Conduct a life cycle cost analysis to assess the total costs of materials over their lifespan. This analysis includes initial costs, maintenance costs, and potential energy savings.

Material Efficiency and Waste Reduction

Optimize material usage and minimize waste by working closely with suppliers, implementing efficient construction practices, and recycling or reusing materials when possible.

Bulk Purchasing and Supplier Relationships

Establish relationships with reliable suppliers and explore bulk purchasing options to negotiate favorable prices for high-quality materials. Building long-term partnerships can lead to cost savings in the long run.

Maintenance and Upkeep of IBS Structures

Regular maintenance and proper upkeep are essential for the longevity and optimal performance of IBS structures. Here are some key maintenance considerations:

Regular Inspections and Repairs

Conduct regular inspections to identify any issues or damages that may arise. Promptly address repairs or replacements to prevent further deterioration and maintain the structural integrity of the building.

Cleaning and Surface Maintenance

Follow recommended cleaning and maintenance practices for different materials used in IBS construction. This includes regular cleaning, sealing, and treatment to preserve the appearance and performance of surfaces.

Moisture Management and Waterproofing

Implement effective moisture management and waterproofing measures to protect IBS structures from water infiltration. This includes proper drainage, sealing of joints, and the use of waterproofing membranes.

Case Studies: Successful IBS Projects

Examining successful IBS projects provides valuable insights into the practical application of high-quality materials. Here are some case studies showcasing the effective use of materials in IBS construction:

Residential IBS Projects

Explore residential projects that showcase the benefits of high-quality materials in terms of comfort, energy efficiency, and durability. These projects highlight the possibilities of creating sustainable and modern homes using IBS.

Commercial IBS Projects

Discover commercial buildings that have successfully utilized high-quality materials in IBS construction. These projects demonstrate the efficiency, cost-effectiveness, and design versatility achievable with IBS methods.

Industrial IBS Projects

Learn about industrial projects that have leveraged high-quality materials to meet specific requirements, such as durability, safety, and functionality. These case studies showcase the adaptability of IBS in industrial settings.

Conclusion

Selecting high-quality materials is crucial for the success of IBS construction projects. From foundations to finishes, each element contributes to the overall quality, durability, and sustainability of the structures. By prioritizing safety, efficiency, and environmental consciousness, IBS construction can revolutionize the industry and pave the way for a more sustainable future.

Frequently Asked Questions (FAQs)

Q: Is IBS construction more expensive than traditional construction methods?

A: While the initial costs of IBS construction may be higher, the long-term benefits in terms of speed, efficiency, and sustainability often outweigh the upfront expenses.

Q: Can IBS structures be customized to meet specific design requirements?

A: Yes, IBS allows for customization and flexibility in design. It offers a wide range of options in terms of sizes, configurations, and finishes.

Q: Are IBS structures suitable for all types of buildings?

A: IBS can be used for various building types, including residential, commercial, and industrial. It offers scalability and adaptability to meet different project needs.

Q: What certifications or standards should I look for when selecting IBS materials?

A: Look for materials that comply with relevant industry standards such as ISO certifications, green building certifications, or local construction codes.

Q: How can I find reliable suppliers and manufacturers of IBS materials?

A: Research and network within the construction industry to find reputable suppliers and manufacturers. Seek recommendations from experienced professionals and consider their track record and reputation.