Blog

Teknologi IBS Dalam Pembinaan Rumah: Apa yang Perlu Anda Tahu?

Teknologi IBS Dalam Pembinaan Rumah: Apa yang Perlu Anda Tahu?

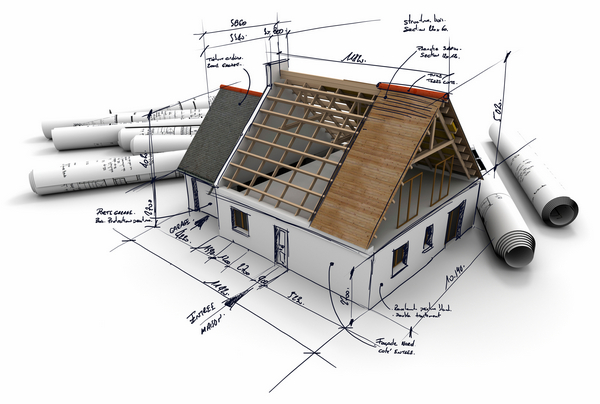

Dalam dunia pembinaan moden, teknologi terus berkembang untuk memastikan bahawa projek pembinaan berjalan dengan lebih cekap, pantas, dan berkualiti tinggi. Salah satu inovasi terkini yang telah merevolusikan industri pembinaan adalah Sistem Pembinaan Berindustri (IBS). Dalam artikel ini, kita akan menyelami dunia IBS, merungkai manfaat dan kelemahan teknologi ini dalam konteks pembinaan rumah, serta menyediakan panduan komprehensif tentang bagaimana teknologi ini membentuk masa depan pembinaan. Jadi, mari kita teroka bersama-sama!

Table of Contents

- Pengenalan kepada Sistem Pembinaan Berindustri (IBS)

- Apa itu Teknologi IBS?

- Jenis-jenis Komponen IBS

- Kelebihan Menganjurkan Teknologi IBS dalam Pembinaan Rumah

- Peningkatan Kecekapan Pembinaan

- Kualiti Pembinaan yang Lebih Konsisten

- Penjimatan Masa dan Tenaga

- Kesan Positif Terhadap Alam Sekitar

- Tantangan dan Kelemahan Teknologi IBS dalam Pembinaan Rumah

- Kos Permulaan yang Lebih Tinggi

- Keperluan Kemahiran Teknikal yang Lebih Tinggi

- Pembatasan Reka Bentuk Kreatif

- Proses Pembinaan Rumah Menggunakan Teknologi IBS

- Perancangan dan Reka Bentuk Awal

- Pengeluaran Komponen IBS

- Pembinaan di Tapak

- Kes Studi: Kejayaan Penggunaan IBS dalam Projek Pembinaan Rumah

- Rumah Mesra Alam Berkonsepkan IBS

- Kualiti Rumah yang Unggul dan Kepuasan Pelanggan

- Inovasi Terkini dalam Teknologi IBS

- Penggunaan Bahan Berkualiti Tinggi

- Peningkatan Sistem Pengangkutan dan Pemasangan

- Kriteria Memilih Pembina IBS yang Tepat

- Pengalaman dan Reputasi

- Kemampuan Menyesuaikan Dengan Kebutuhan Pelanggan

- FAQ Tentang Teknologi IBS dalam Pembinaan Rumah

- Apakah kelebihan utama menggunakan teknologi IBS dalam pembinaan rumah?

- Adakah kos penggunaan teknologi IBS lebih tinggi daripada kaedah konvensional?

- Bagaimana pengaruh teknologi IBS terhadap keselamatan dan kualiti pembinaan?

- Adakah reka bentuk rumah terhad menggunakan teknologi IBS?

- Apa yang membezakan pembina IBS yang berkualiti?

- Adakah teknologi IBS sesuai untuk projek rumah berskala besar?

- Bagaimana saya boleh memulakan projek pembinaan rumah menggunakan teknologi IBS?

Kami akan bina rumah berdasarkan budget yang anda tentukan. Kos ini merangkumi kerja-kerja awalan & pembinaan struktur rumah. Construction: RM160 psf

Preliminary: RM20,000 Construction: RM190 psf

Preliminary: RM20,000 Hanya Masukkan Angka, Tanpa Koma ( , ). Contoh: 1000 Bina rumah lebih mudah dengan pembiayaan kewangan. Additional Cost: RM4 psf No Additional Cost No Additional Cost Kos ini merangkumi Fee Arkitek, Jurutera & PMC. Kelulusan PBT adalah wajib jika anda menggunakan pembiayaan LPPSA/BANK. Consultant Fee: RM50,000 No Additional Cost No Additional Cost Kami juga ada sediakan servis lukis pelan rumah untuk anda. Kami boleh bantu untuk mohon meter tersebut (optional) TNB & SYABAS: RM4,500 No Additional Cost Senarai penuh dan perbezaaan 2 spesifikasi ini akan dilampirkan dalam email anda. Full Spec: RM49 psf Low Spec: RM9 psf Sila isi butiran berikut. Kami akan hantar quotation & senarai penuh spesifikasi ke email anda.

BERAPAKAH KOS BINA RUMAH SAYA?

Terima kasih, kami akan hubungi anda secepat mungkin.

Rumah 1 Tingkat Ataupun 2 Tingkat?

Berapakah Luas Keseluruhan Rumah Anda?

Apakah Jenis Pembiayaan Rumah Anda?

Anda Perlu Mohon Kelulusan Pelan Bangunan?

Sudah Ada Pelan Rumah Tersebut?

Meter Kekal TNB & SYABAS

Full Spec ataupun Low Spec?

Anggaran Kos Bina Rumah Anda Adalah :

Ringkasan

Deskripsi

Informasi

Kuantiti

Kos

Discount : Total :

1. Pengenalan kepada Sistem Pembinaan Berindustri (IBS)

Apa itu Teknologi IBS?

Sistem Pembinaan Berindustri (IBS) adalah pendekatan pembinaan yang menggabungkan penghasilan komponen pembinaan di luar tapak dengan penyusunan dan pemasangan yang lebih sistematik dan terkawal di tapak pembinaan. IBS melibatkan penggunaan komponen standard yang telah dibuat di kilang dan dikirim ke tapak pembinaan untuk dipasang bersama-sama. Teknologi ini bertujuan untuk meningkatkan efisiensi, kualiti, dan produktiviti pembinaan.

Jenis-jenis Komponen IBS

Terdapat beberapa jenis komponen IBS yang biasanya digunakan dalam pembinaan rumah, antaranya termasuk:

- Panel Dinding Prategang: Dinding beton yang telah dicetak di kilang dengan tali dawai prategang untuk meningkatkan daya tahan dan kekuatan.

- Sistem Paip dan Elektrik Pramatang: Modul paip dan kabel elektrik yang telah dipasang sebelumnya di dalam komponen dinding atau lantai.

- Komponen Struktur Rangka Baja: Rangka baja yang telah dihasilkan dengan ketepatan di kilang dan dipasang di tapak.

2. Kelebihan Menganjurkan Teknologi IBS dalam Pembinaan Rumah

Peningkatan Kecekapan Pembinaan

Dalam pembinaan menggunakan teknologi IBS, kerja-kerja pembinaan dapat diselesaikan dengan lebih cepat kerana sebahagian besar komponen telah disediakan terlebih dahulu. Ini mengurangkan masa yang diperlukan untuk membangunkan struktur asas rumah.

Kualiti Pembinaan yang Lebih Konsisten

Komponen IBS dihasilkan dalam persekitaran kilang yang terkawal. Ini bermakna kualiti bahan dan kerja-kerja pembuatan lebih terjamin dan konsisten. Keputusan akhir adalah rumah yang lebih berkualiti dan tahan lama.

Penjimatan Masa dan Tenaga

Penggunaan teknologi IBS mengurangkan kerja-kerja manual yang dilakukan di tapak pembinaan. Ini membantu mengurangkan peningkatan tenaga manusia dan mengurangkan risiko kemalangan buruh.

Kesan Positif Terhadap Alam Sekitar

Penggunaan IBS cenderung menghasilkan lebih sedikit sisa bahan pembinaan di tapak kerja. Ini membantu mengurangkan pencemaran alam sekitar dan meningkatkan amalan pembangunan lestari.

3. Tantangan dan Kelemahan Teknologi IBS dalam Pembinaan Rumah

Kos Permulaan yang Lebih Tinggi

Pengenalan teknologi IBS memerlukan pelaburan awal yang lebih besar dalam pembelian komponen dan penyesuaian infrastruktur di kilang. Walau bagaimanapun, kos ini boleh diimbangi oleh penjimatan masa dan tenaga dalam jangka panjang.

Keperluan Kemahiran Teknikal yang Lebih Tinggi

Penggunaan IBS memerlukan kemahiran teknikal yang lebih tinggi dalam perancangan, pengeluaran, dan pemasangan komponen. Pekerja yang tidak mahir boleh mengakibatkan masalah berkaitan kualiti dan keselamatan.

Pembatasan Reka Bentuk Kreatif

Beberapa jenis reka bentuk mungkin tidak sesuai dengan teknologi IBS kerana keperluan penghasilan komponen standard. Ini boleh menyekat kebebasan dalam reka bentuk kreatif rumah.

4. Proses Pembinaan Rumah Menggunakan Teknologi IBS

Perancangan dan Reka Bentuk Awal

Proses bermula dengan perancangan dan reka bentuk awal rumah. Ini melibatkan pemilihan komponen IBS yang sesuai dengan rekabentuk yang dikehendaki.

Pengeluaran Komponen IBS

Selepas reka bentuk disiapkan, komponen IBS seperti panel dinding, rangka baja, dan sistem paip elektrik akan dihasilkan di kilang. Ini termasuk kerja-kerja seperti mencetak, mengawal kualiti, dan memastikan sesuai dengan piawaian.

Pembinaan di Tapak

Setelah semua komponen siap, mereka akan dikirim ke tapak pembinaan dan dipasang bersama-sama. Proses ini biasanya lebih pantas dan sistematik berbanding pembinaan konvensional.

5. Kes Studi: Kejayaan Penggunaan IBS dalam Projek Pembinaan Rumah

Rumah Mesra Alam Berkonsepkan IBS

Masjaya Eco Construction telah membuktikan keberkesanan IBS dalam projek Rumah Mesra Alam. Dengan penggunaan panel dinding prategang dan komponen IBS lain, rumah ini tidak hanya mempunyai kualiti yang tinggi, tetapi juga mengurangkan kesan negatif terhadap alam sekitar.

Kualiti Rumah yang Unggul dan Kepuasan Pelanggan

Penggunaan IBS telah membuktikan bahawa rumah-rumah yang dibina menggunakan teknologi ini mempunyai kualiti yang lebih baik dan kepuasan pelanggan yang lebih tinggi. Ini adalah hasil daripada kualiti pembinaan yang konsisten dan ketepatan dalam pemasangan komponen.

6. Inovasi Terkini dalam Teknologi IBS

Penggunaan Bahan Berkualiti Tinggi

Sekarang, terdapat usaha untuk menggunakan bahan berkualiti tinggi dalam penghasilan komponen IBS. Ini memberi kelebihan tambahan dalam hal daya tahan dan kualiti jangka panjang rumah.

Peningkatan Sistem Pengangkutan dan Pemasangan

Peningkatan dalam sistem pengangkutan dan pemasangan komponen IBS turut memberi manfaat dalam meningkatkan kecekapan dalam proses pembinaan dan mengurangkan risiko kerosakan semasa pengangkutan.

7. Kriteria Memilih Pembina IBS yang Tepat

Pengalaman dan Reputasi

Pilihlah pembina IBS yang mempunyai pengalaman dalam menggunakan teknologi ini dan mempunyai reputasi baik dalam menghasilkan rumah berkualiti tinggi.

Kemampuan Menyesuaikan Dengan Kebutuhan Pelanggan

Pilih pembina yang boleh menyesuaikan teknologi IBS dengan keperluan reka bentuk dan kehendak pelanggan. Kemampuan untuk memberikan hasil yang memuaskan pelanggan adalah penting.

8. FAQ Tentang Teknologi IBS dalam Pembinaan Rumah

1. Apakah kelebihan utama menggunakan teknologi IBS dalam pembinaan rumah?

Kelebihan utama IBS termasuk peningkatan kecekapan, kualiti yang lebih konsisten, penjimatan masa dan tenaga, serta impak positif terhadap alam sekitar.

2. Adakah kos penggunaan teknologi IBS lebih tinggi daripada kaedah konvensional?

Walaupun kos permulaan lebih tinggi, penjimatan masa dan tenaga dalam jangka panjang boleh seimbangkan kos ini.

3. Bagaimana pengaruh teknologi IBS terhadap keselamatan dan kualiti pembinaan?

Teknologi IBS dapat meningkatkan keselamatan dan kualiti pembinaan dengan penggunaan komponen standard yang berkualiti terjamin.

4. Adakah reka bentuk rumah terhad menggunakan teknologi IBS?

Terdapat beberapa pembatasan dalam reka bentuk kreatif, tetapi pilihan komponen IBS yang luas membolehkan penyesuaian yang mencukupi.

5. Apa yang membezakan pembina IBS yang berkualiti?

Pembina berkualiti tinggi mempunyai pengalaman dalam teknologi IBS dan mampu menyesuaikan dengan kehendak pelanggan.

6. Adakah teknologi IBS sesuai untuk projek rumah berskala besar?

Ya, teknologi IBS sesuai untuk projek rumah berskala besar kerana ia membantu meningkatkan kecekapan dan kualiti pembinaan.

7. Bagaimana saya boleh memulakan projek pembinaan rumah menggunakan teknologi IBS?

Hubungi Masjaya Eco Construction di 016-3547300 untuk mendapatkan panduan dan maklumat lanjut tentang memulakan projek pembinaan rumah menggunakan teknologi IBS.

Kesimpulan

Teknologi IBS telah membawa perubahan besar dalam industri pembinaan, terutama dalam pembinaan rumah. Dengan kelebihan seperti peningkatan kecekapan, kualiti yang lebih baik, dan kesan positif terhadap alam sekitar, IBS adalah pilihan yang semakin popular di kalangan pemaju dan pelanggan. Walaupun terdapat beberapa cabaran, perkembangan dan inovasi dalam teknologi ini terus membantu mengatasi halangan tersebut. Jadi, jika anda mencari cara untuk membina rumah yang berkualiti tinggi dan efisien, teknologi IBS adalah jawapannya.

Jangan ragu untuk menghubungi Masjaya Eco Construction di 016-3547300 jika anda mempunyai sebarang pertanyaan atau memerlukan penjelasan lanjut mengenai penggunaan teknologi IBS dalam pembinaan rumah anda. Kami sedia membantu anda merancang dan melaksanakan projek pembinaan rumah dengan kecekapan dan kualiti yang tinggi menggunakan teknologi IBS yang terkini.

kontraktor rumah

bina rumah

pinjaman lppsa

pengeluaran kwsp

spesifikasi rumah

pelan rumah

rekabentuk rumah

bina rumah atas tanah sendiri

kontraktor rumah selangor